The step of corn syrup extracted from corn consists mainly of two parts, namely corn starch extraction and production of syrup with corn starch.

Corn syrup extraction process

Corn syrup extraction process

Part Ⅰ: Corn Starch Extraction:

Corn starch extraction is a product made from corn kernels, put corn kernels in sulfurous acid to immerse, then crushed, sieved, separated and washed, and dehydrated and dried to get dry corn starch. Corn kernels have a moisture content of 12-16%, starch 70%-72%, protein 8%-11%, fat 4%-6%, ash 1.2%-1.6%, and fiber 5%-7%. There are many methods for making starch from corn. The basic process of corn starch extraction is as follows: corn -- cleaning - soaking - coarse crushing - separation of embryo - grinding - separating fiber - separating protein - cleaning - centrifugation - drying - starch.

Corn starch is mainly used in medicine, food, chemical, textile and other industries. It can produce sucrose, high maltose syrup, glucose, modified starch, soluble starch, cyclodextrin, acid starch, oxidized starch and high fructose syrup. Raw materials for the production of enzyme preparations, MSG, amino acids and raw materials for the fermentation of antibiotics. In recent years, with the development of production in various industries, corn starch has been favored in the market for its wide application, excellent performance and moderate price. At the same time, corn starch is also the most widely used raw material for the preparation of starch syrup.

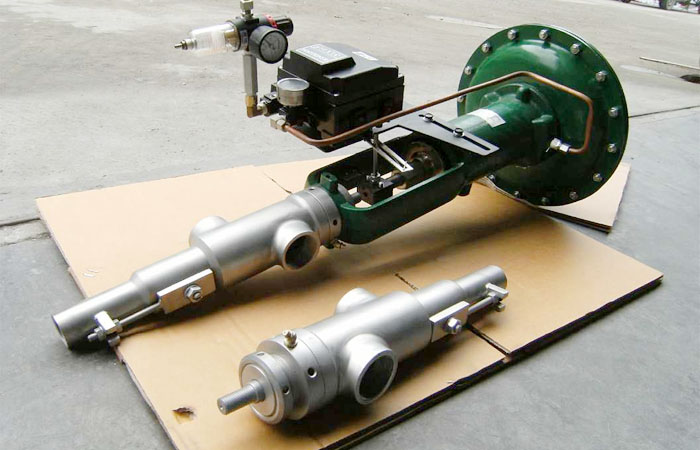

Corn syrup production equipment

Corn syrup production equipment

Part II: Production of cornstarch syrup:

At present, the most popular process for producing starch syrup is the double enzyme method. Enzyme liquefaction and enzyme saccharification process is called double enzymatic method. Double enzymatic method for producing syrup is uses special enzyme preparation as a catalyst, the reaction conditions are mild and the compound decomposition reaction is less. Therefore, the corn syrup can be produced by double enzymatic method. It is the most ideal sugar-making method to improve the conversion rate and sugar concentration and improve the quality of sugar liquid.

First, the starch is adjusted; the pH is adjusted to 6.0 with soda ash, and then the high temperature resistant a-amylase is added and stirred uniformly. The starch slurry after the adjustment is gelatinized, the purpose of which is to break the crystal structure of the starch molecules and initially aggregate the proteins. After the liquefaction is uniform, the qualified liquefied liquid is obtained, that is, the reasonable DE value, the appearance is transparent, the white precipitate is not formed, the viscosity is low, the protein flocculates well, and the liquefaction completed.

The pH of the feed was then adjusted to 4.5 with acid and the human saccharification enzyme was added. After a certain saccharification cycle, the feed liquid reaches the expected DE value. At this time, the decolorization of the liquid and the purification of the ion exchange can be performed. The purified corn syrup is concentrated by evaporation in a three-effect evaporator to reach the desired concentration.

- Prev:Nothing

- Next:How is corn syrup processed?

Leave A Message About How is corn syrup extracted?

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...