Corn syrup plant

2018-08-16

/Syrup Processing

Corn syrup is produced from yellow dent corn. When wet milled, about 2.3 litres of corn are required to yield an average of 947g of starch, to produce 1 kg of glucose or dextrose syrup. And we can install the corn syrup plant fou you.

Below we mainly introduce the corn syrup plant operation process and the main equipment:

MIXTING STARCH SLURRY

Mixing starch and certain water to get the certain density slurry, then adding certain enzyme, and maintaining a certain temperature for particular time to make sure the proceeding of physical reaction between starch and enzyme.

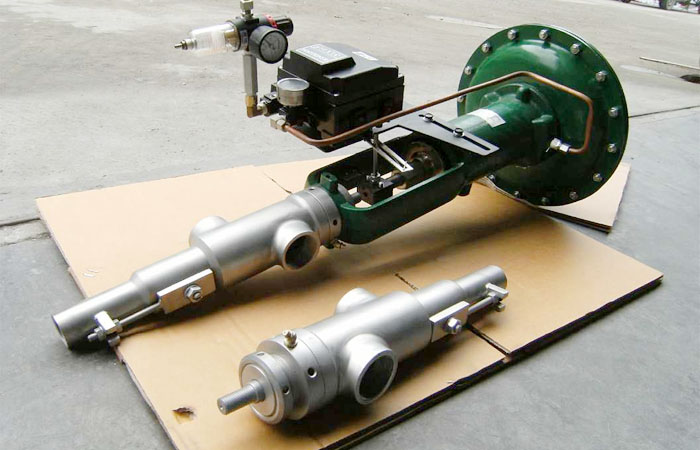

Corn syrup production equipment

LIQUEFACTION PROCESS

Pumping starch slurry into the mixing tank, there could be some brown floater appearing on the surface of mixing tank, which is likely to be caused by high protein content. It will cause high dosage of activated carbon, increasing the load of ion exchange, and reducing the service life of ion-exchange resin, so we must ensure that the starch milk protein content is below 0.5%. In order to make full use of the mother liquor, the part starch milk can be recycled in the mixing slurry process, and the normal return amount can reach up to 2/3. The overused in corn syrup plant will affect the quality. Average concentration is 35% - 36%. Mixing temperature is 29 ℃ -34 ℃ . Then pumping starch slurry into the ejector.

Large and medium-sized corn syrup plant enterprises flow rate is 25-40 m3 / h; steam pressure is 0.4 Mpa; liquefied liquid temperature is 99 ℃ . After that entering the laminar flow tank for heat preservation of 60 minutes, and then into maintaining tank. Put the liquefied liquid into the second ejector. The steam injection pressure control is 0.2 Mpa; the temperature control is 130℃ to 134.6℃. Liquefied liquid will come into the high temperature maintain tank and then secondary flash cooling tank. The liquid temperature lower 64℃ to 60℃ to neutralize, then coming into the neutralization tank, adjusting the pH value to 4.4-4.5 for preparing glycosylated in corn syrup plant.

Filter press

DECARBOM PROCESS

Liquid dextrin which has been through high temperature injection shall move into filter press for mechanical extrusion in corn syrup plant.The deproteinization process will separate the protein and other solid impurities from liquid dextrin by filter press. After that, the liquid dextrin will be pumped to next process, the protein cake will be left for sale.

SACCHARIFICATION PROCESS

The liquefied liquid (solid content of 30% -35%) is pumped to the saccharification tank and cooled to 60°C. Adding acid to adjust the pH to around 4.5. The brix is 31-32Bx; the adjusted concentration is 34.67% -35.6%; adding the saccharification enzyme is equivalent to 0.45-0.58L / ton dry starch. The liquefied liquid DE value is 28.85% -31.53%, the pumping time is 4-6 hours for one tank. Each tank of saccharification time is 50 hours for corn syrup plant operation. The DE value is about 95-97 when finished. The saccharification liquid is pumped into the pre-coated perlite drum filter to separate protein, and then entering the third time injectors for enzyme deactivation after saccharification. The third injection temperature is about 99℃; the injection pressure is 0.39Mpa; and the saccharification liquid yield is about 98% -105%.

Corn syrup processing

DECOLORIZATION & DECARBURIZATION

The normal sequence about this part in corn syrup plant is:The first decolorization→the first decarburization→The second decolorization→the second decarburization.

The saccharification liquid will be pumped into a decolorization tank, adding the waste activated carbon of the second plate frame filter pressing then killing enzyme and decolorization for 30 minutes. Then pumping the discolored syrup liquid into the first plate frame, the activated carbon will be filter out. Pumping the first discolored syrup liquid into the second decolorization tank, adding new activated carbon, decolorization for 30 minutes. The second decolored syrup liquid is subjected to plate and frame filtration, and then it will be pumped into the ion exchange system storage tank through the plate heat exchanger in corn syrup plant.

ION EXCHANGE

This process aims to remove the impurities and different ions to ensure the purity of syrup. Normally, it needs the anion-cation process, pump the discolored syrup liquid into the storage tank, keep the temperature about 30 ℃, And then pump the liquid syrup into the cation exchange column to remove the Ca2+ and Mg2+ etc; and then pump syrup into the cathode column to remove the negative ions. Finally pump the syrup into the adjusting pillars for conductance and pH adjustment. Corn syrup plant resin regeneration: after soaking resin for a certain time, open all the valve, start the deionized water pump to wash resin. At start control the water flow in small volume and increase volume after acid (or alkali) washed out.

Ion exchange column

CONCENTRATION:

After ion exchange process in corn syrup plant, the syrup will be pumped into the storage tank, after heating exchange and then enter into the syrup evaporator. Evaporator commonly used multiple-effect evaporator for example three-effect etc. Pump the ion exchange liquid syrup into the three-effect evaporator. The first effect evaporator vacuum degree is 0.01-0.03Mpa, the temperature is about 105 ℃ , the second-effect evaporator vacuum degree is 0.015-0.028Mpa, the temperature is 84 ℃ -90 ℃ , the third-effect evaporation vacuum degree is 0.04-0.05Mpa, the temperature is 55 ℃-60 ℃ etc. After evaporation, it will be the high density liquid syrup according to the requirement.

Finally, any questions about the corn syrup plant operation and installation, please conact us freely.

Below we mainly introduce the corn syrup plant operation process and the main equipment:

MIXTING STARCH SLURRY

Mixing starch and certain water to get the certain density slurry, then adding certain enzyme, and maintaining a certain temperature for particular time to make sure the proceeding of physical reaction between starch and enzyme.

Corn syrup production equipment

LIQUEFACTION PROCESS

Pumping starch slurry into the mixing tank, there could be some brown floater appearing on the surface of mixing tank, which is likely to be caused by high protein content. It will cause high dosage of activated carbon, increasing the load of ion exchange, and reducing the service life of ion-exchange resin, so we must ensure that the starch milk protein content is below 0.5%. In order to make full use of the mother liquor, the part starch milk can be recycled in the mixing slurry process, and the normal return amount can reach up to 2/3. The overused in corn syrup plant will affect the quality. Average concentration is 35% - 36%. Mixing temperature is 29 ℃ -34 ℃ . Then pumping starch slurry into the ejector.

Large and medium-sized corn syrup plant enterprises flow rate is 25-40 m3 / h; steam pressure is 0.4 Mpa; liquefied liquid temperature is 99 ℃ . After that entering the laminar flow tank for heat preservation of 60 minutes, and then into maintaining tank. Put the liquefied liquid into the second ejector. The steam injection pressure control is 0.2 Mpa; the temperature control is 130℃ to 134.6℃. Liquefied liquid will come into the high temperature maintain tank and then secondary flash cooling tank. The liquid temperature lower 64℃ to 60℃ to neutralize, then coming into the neutralization tank, adjusting the pH value to 4.4-4.5 for preparing glycosylated in corn syrup plant.

Filter press

DECARBOM PROCESS

Liquid dextrin which has been through high temperature injection shall move into filter press for mechanical extrusion in corn syrup plant.The deproteinization process will separate the protein and other solid impurities from liquid dextrin by filter press. After that, the liquid dextrin will be pumped to next process, the protein cake will be left for sale.

SACCHARIFICATION PROCESS

The liquefied liquid (solid content of 30% -35%) is pumped to the saccharification tank and cooled to 60°C. Adding acid to adjust the pH to around 4.5. The brix is 31-32Bx; the adjusted concentration is 34.67% -35.6%; adding the saccharification enzyme is equivalent to 0.45-0.58L / ton dry starch. The liquefied liquid DE value is 28.85% -31.53%, the pumping time is 4-6 hours for one tank. Each tank of saccharification time is 50 hours for corn syrup plant operation. The DE value is about 95-97 when finished. The saccharification liquid is pumped into the pre-coated perlite drum filter to separate protein, and then entering the third time injectors for enzyme deactivation after saccharification. The third injection temperature is about 99℃; the injection pressure is 0.39Mpa; and the saccharification liquid yield is about 98% -105%.

Corn syrup processing

DECOLORIZATION & DECARBURIZATION

The normal sequence about this part in corn syrup plant is:The first decolorization→the first decarburization→The second decolorization→the second decarburization.

The saccharification liquid will be pumped into a decolorization tank, adding the waste activated carbon of the second plate frame filter pressing then killing enzyme and decolorization for 30 minutes. Then pumping the discolored syrup liquid into the first plate frame, the activated carbon will be filter out. Pumping the first discolored syrup liquid into the second decolorization tank, adding new activated carbon, decolorization for 30 minutes. The second decolored syrup liquid is subjected to plate and frame filtration, and then it will be pumped into the ion exchange system storage tank through the plate heat exchanger in corn syrup plant.

ION EXCHANGE

This process aims to remove the impurities and different ions to ensure the purity of syrup. Normally, it needs the anion-cation process, pump the discolored syrup liquid into the storage tank, keep the temperature about 30 ℃, And then pump the liquid syrup into the cation exchange column to remove the Ca2+ and Mg2+ etc; and then pump syrup into the cathode column to remove the negative ions. Finally pump the syrup into the adjusting pillars for conductance and pH adjustment. Corn syrup plant resin regeneration: after soaking resin for a certain time, open all the valve, start the deionized water pump to wash resin. At start control the water flow in small volume and increase volume after acid (or alkali) washed out.

Ion exchange column

CONCENTRATION:

After ion exchange process in corn syrup plant, the syrup will be pumped into the storage tank, after heating exchange and then enter into the syrup evaporator. Evaporator commonly used multiple-effect evaporator for example three-effect etc. Pump the ion exchange liquid syrup into the three-effect evaporator. The first effect evaporator vacuum degree is 0.01-0.03Mpa, the temperature is about 105 ℃ , the second-effect evaporator vacuum degree is 0.015-0.028Mpa, the temperature is 84 ℃ -90 ℃ , the third-effect evaporation vacuum degree is 0.04-0.05Mpa, the temperature is 55 ℃-60 ℃ etc. After evaporation, it will be the high density liquid syrup according to the requirement.

Finally, any questions about the corn syrup plant operation and installation, please conact us freely.

- Prev:Sterilization and pollution prevention in glucose syrup processing

- Next:Corn syrup production steps

Leave A Message About Corn syrup plant

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- Ion exchange resin equiped in ion exchange column, its necessary for t...

- When high maltose corn syrup is produced in industrial production,the ...

- Here bellow introduces the sterilization and pollution prevention when...

- And we can install the corn syrup plant fou you.Corn syrup is produced...

- Corn syrup production steps introduce the way of how to make glucose s...

- The liquid glucose manufacturing process completed by one complete set...

- Corn syrup production process is a process of converting corn into syr...

- DOING adopt the modern and advanced technology for liquid syrup manufa...

- Starch syrup manufacturing process introductions and the main equipmen...

- Syrup evaporator is key equipment in glucose production line,there are...