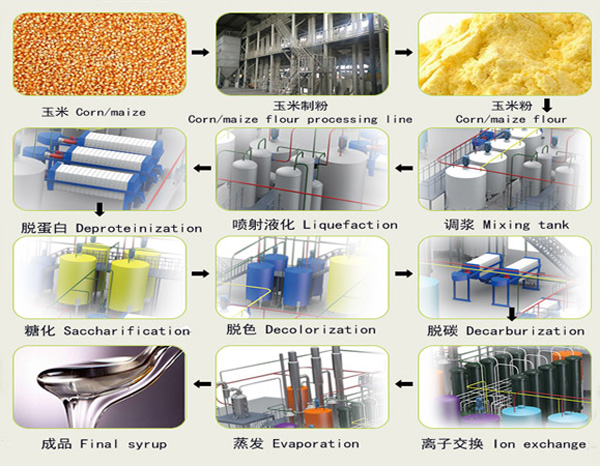

Liquid glucose manufacturing process

2018-07-23

/Syrup Processing

The liquid glucose manufacturing process completed by one complete set of glucose manufacturing machine and professional method, nowadays, suggest you use the enzyme method for starch hydrocylis to manufacturer the glucose, this is the most high efficient method for liquid glucose manufacturing process, guarantee the glucose products quality.

Below is liquid glucose manufacturing process divided section brief description:

Liquid glucose manufacturing process from corn

1. Mixing and liquefying process: mixing the corn flour / starch with water, adjust the PH value to 5.0-6.0, suitable for following starch hydrolysis, after mixing add liquifying enzyme, use ejector to complete the liquefaction process. Then we can get a suitable liquid can be prepared for saccharification.

2. Saccharify: this is the second process which requests enzymes add, use saccharifying enzymes, adjust the corn starch liquid temperature to 58-60 degree, after it reach the request DE value can put into next process. Saccharify process performance decided the liquid glucose syrup manufacturing effect and products quality. This is an important and basic step of liquid glucose manufacturing process. After this process, we can get glucose liquid.

Saccharification tank

3. Liquid glucose decolorizing: uses second time decolorizing process to get bright syrup. This production process generally complete by plate and frame filter press. The plate and frame filter press equipped with special filter cloth, good performance and high speed for syrup decoloring, a refining process in the liquid glucose manufacturing process.

4. Filtration: this process adopt drum filter to remove soluble protein, decrease the protein content in glucose liquid of liquid glucose manufacturing process.

5. Ion exchange system: adjust the temperature and PH value, remove irons, salt and ash, according to the ion exchange column, we can get pure liquid glucose. About liquid glucose manufacturing process, this ion exchange system is an essential step. And the ion exchange resin can be regeneration by simple way.

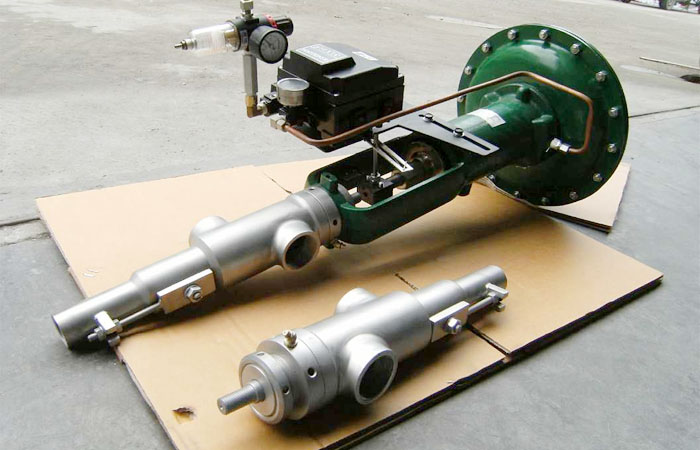

Ion exchange column

6. Liquid glucose evaporation: under vacuum condation to make heating and evaporation, make the syrup concentration meet the standards, after the temperature reduce, can pump into the storage tank.

To sum up, among is our liquid glucose manufacturing process introduction. If you plan to start a business of liquid glucose production, Doing Company can manufacturer and shippments the all equipments for you, and the main machine used for liquid glucose manufacturing process include: Mixing tank, Liquefaction tank & ejector, Plate frame filter press machine, Saccharification tank, Ion exchange column, Syrup evaporator, Storage tank.

Evaporation

Compared with other liquid syrup equipments manufacturers, our liquid glucose production equipments is easy to handle, highly dependable, completely automation control with smart design. Under the liquid glucose manufacturing process, our equipments can achieve no waste water discharge, full sealing process, use the special enzyme for starch hydrolysis to get liquid glucose, this is the most advanced and highest efficiency liquid glucose manufacturing process method. And our company is responsible for the your liquid glucose equipments design, installation, commissioning and training the operator, give you perfect service.

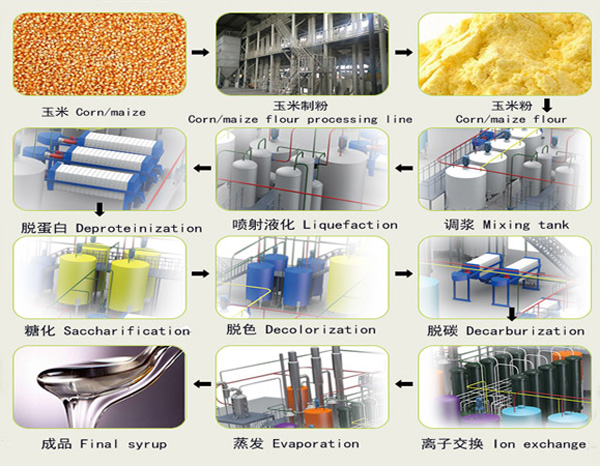

Below is liquid glucose manufacturing process divided section brief description:

Liquid glucose manufacturing process from corn

1. Mixing and liquefying process: mixing the corn flour / starch with water, adjust the PH value to 5.0-6.0, suitable for following starch hydrolysis, after mixing add liquifying enzyme, use ejector to complete the liquefaction process. Then we can get a suitable liquid can be prepared for saccharification.

2. Saccharify: this is the second process which requests enzymes add, use saccharifying enzymes, adjust the corn starch liquid temperature to 58-60 degree, after it reach the request DE value can put into next process. Saccharify process performance decided the liquid glucose syrup manufacturing effect and products quality. This is an important and basic step of liquid glucose manufacturing process. After this process, we can get glucose liquid.

Saccharification tank

3. Liquid glucose decolorizing: uses second time decolorizing process to get bright syrup. This production process generally complete by plate and frame filter press. The plate and frame filter press equipped with special filter cloth, good performance and high speed for syrup decoloring, a refining process in the liquid glucose manufacturing process.

4. Filtration: this process adopt drum filter to remove soluble protein, decrease the protein content in glucose liquid of liquid glucose manufacturing process.

5. Ion exchange system: adjust the temperature and PH value, remove irons, salt and ash, according to the ion exchange column, we can get pure liquid glucose. About liquid glucose manufacturing process, this ion exchange system is an essential step. And the ion exchange resin can be regeneration by simple way.

Ion exchange column

6. Liquid glucose evaporation: under vacuum condation to make heating and evaporation, make the syrup concentration meet the standards, after the temperature reduce, can pump into the storage tank.

To sum up, among is our liquid glucose manufacturing process introduction. If you plan to start a business of liquid glucose production, Doing Company can manufacturer and shippments the all equipments for you, and the main machine used for liquid glucose manufacturing process include: Mixing tank, Liquefaction tank & ejector, Plate frame filter press machine, Saccharification tank, Ion exchange column, Syrup evaporator, Storage tank.

Evaporation

Leave A Message About Liquid glucose manufacturing process

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- Ion exchange resin equiped in ion exchange column, its necessary for t...

- When high maltose corn syrup is produced in industrial production,the ...

- Here bellow introduces the sterilization and pollution prevention when...

- And we can install the corn syrup plant fou you.Corn syrup is produced...

- Corn syrup production steps introduce the way of how to make glucose s...

- The liquid glucose manufacturing process completed by one complete set...

- Corn syrup production process is a process of converting corn into syr...

- DOING adopt the modern and advanced technology for liquid syrup manufa...

- Starch syrup manufacturing process introductions and the main equipmen...

- Syrup evaporator is key equipment in glucose production line,there are...