About how is corn syrup processed, in there, Doing Company will give you the answer. The corn syrup processing mainly divided into two parts: corn starch extraction and starch syrup processing.

Corn syrup production process

Corn syrup production process

Starting from corn, the starch is produced by wet milling method, a part of the refined starch milk obtained is directly dehydrated and dried to obtain corn starch (good for storage), and another part of the refined starch milk is added with an auxiliary material such as an enzyme, and then directly subjected to liquefaction, saccharification, refining and the like to directly produce starch syrup. In this way, the corn syrup processing can be prevented from being affected by the start or not of the starch production workshop. The syrup can be produced from starch milk, or the starch syrup can be prepared by directly adding water to the corn starch, thereby the production can be adjusted according to the market conditions of corn starch and starch syrup.

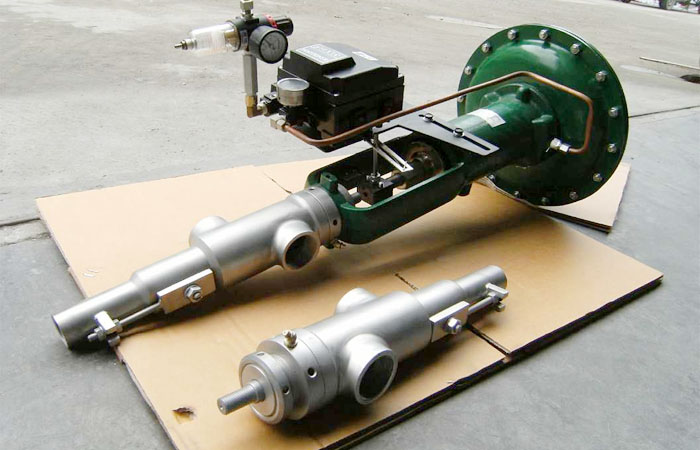

Corn syrup processing equipment

Corn syrup processing equipment

Below is the corn syrup production process introduction(use dry starch as an example):

1. Mixing process. Mixing corn starch with water to get certain required density starch slurry. It's better to use soften water, which can reduce ion impurities.

2. Liquefaction process. Jet cooking machine and liquefaction tank are used in the procedure. Jet cooking makes temperature increase quickly in short time, resulting in starch granules absorb water quickly and expend together to get transparent paste liquid, which is called gelatinization. Gelatinization provide better condition for the later liquefaction process. In liquefaction process, after adding enzyme, temperature is maintained at required temperature to make starch slurry liquefied completely. All the reaction will be proceed in the liquefaction tank.

3. Saccharification process. It's the key process to how is corn syrup processed as required, which directly determines DE value of final products. In fact, the saccharification process is to create an environment suitable for saccharification enzymes. The key point is pH and temperature adjustment. The final hydrolysis of the sugars gives a crude saccharification solution.

Corn syrup processing equipment

Corn syrup processing equipment

4. Decolorization and decarburization process. The purpose of decolorization is to remove organic impurities dissolved in water. Most organic impurities are colored organic impurities. We add powdered activated carbon that has strong adsorption ability to organic impurities. And activated carbon is insoluble in water, and then we can use filter press machine to finish decarburization process for how to make glucose syrup without cream of tartar. The filter removes the activated carbon as well as removes organic impurities from the sugar solution.

5. Ion exchange process. After the water-insoluble impurities and organic impurities in the sugar liquid are removed, there still contain many inorganic impurities dissolved in water. These impurities exist in the form of cations and anions in water. The purpose of ion exchange is to remove these water-soluble inorganic impurities.

6. Evaporation process. After previous steps, impurities in the liquid glucose are mostly removed. The last step will use evaporator to remove excess water and get final glucose syrup in certain density. Three-effect evaporator is commonly used.

Corn syrup equipment manufacturing

Corn syrup equipment manufacturing

Advantages and features of the corn syrup processing technology from Doing Company:

1. Directly use the refined starch milk in the corn starch production workshop to produce starch syrup. First, it can reduce the cost of dehydration and drying of starch milk. Second, avoid the trouble of adding water to adjust the starch when using finished starch (dry starch).

2. After liquefying with high-temperature a-amylase, the starch syrup is produced by fungal amylase to make the content of maltose more than 50%.

3. By changing the variety and process parameters of the enzyme, it can also produce glucose syrup, syrup syrup, high maltose syrup, oligo-isoma syrup, fructose syrup and other products. If a spray drying tower is added, a maltodextrin product can be produced; and a crystallizing tank can be used to produce crystalline glucose or other varieties of crystalline sugar for injection and oral administration. It can also be used as a saccharification workshop for the production of fermented products (monosodium glutamate, amino acids, glycerol, etc.).

Leave A Message About How is corn syrup processed?

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...