Corn glucose manufacturing plant

Professional corn glucose manufacturing plant introduction,corn glucose manufacturing plant production process,and our corn glucose syrup manufacturing plant features.

- Ms Elina Wu

- Phone:0086 135 2661 5783

- Email:sales@syrupmachine.com

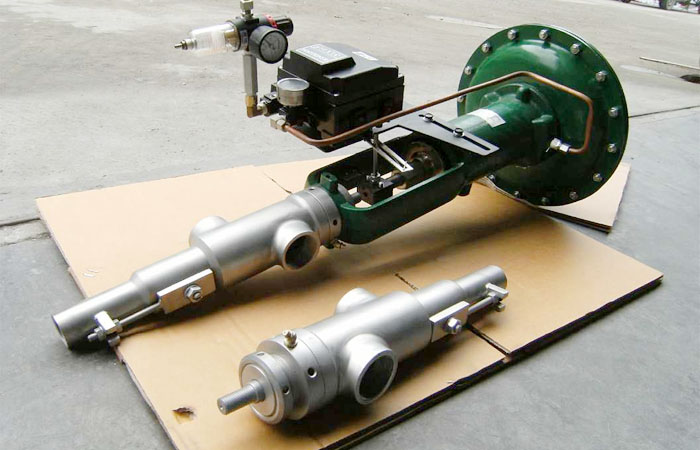

Before conversion of corn starch to glucose, the starch must be separated from the plant material. This includes removing fibre and protein, protein produces off-flavours and colours due to the Maillard reaction, fibre is insoluble and has to be removed to allow the starch to become hydrated. The deprotein process in corn glucose manufacturing plant usually complete by our plate frame filter machine.

Plate frame filter press

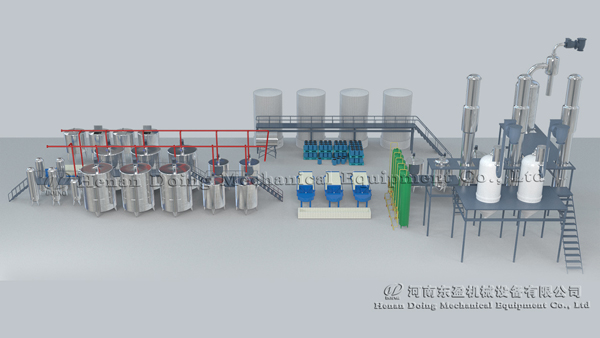

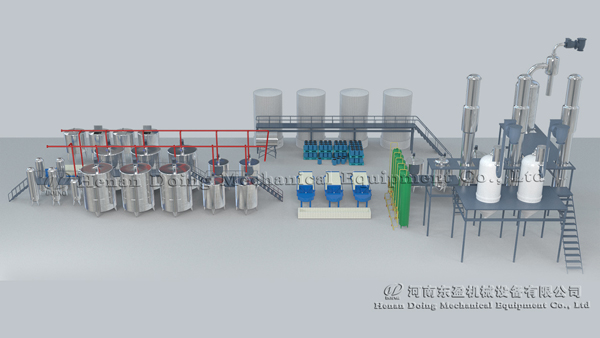

The technology process of corn glucose manufacturing plant as below: extracting syrup from corns, enzymatic hydrolysis, chemical synthesis, separation and purification.Next will introduce DOING corn glucose manufacturing plant main process:

The starch needs to be swelled to allow the enzymes to act upon it. When grain is used, sulfur dioxide is added to prevent spoilage. By heating the ground, cleaned feedstock, starch gelatinization takes place: the intermolecular bonds of the starch molecules are broken down, allowing the hydrogen bonding sites to engage more water. This irreversibly dissolves the starch granule, so the chains begin to separate into an amorphous form. This prepares the starch can be used for hydrolysis. So actually this is the first step for corn glucose manufacturing plant process.

Hydrolysis by enzyme:

Glucose syrup can be produced by acid hydrolysis, enzyme hydrolysis, or a combination of the two. However, overall consideration, the enzyme hydrolysis is the best choice, no corrode the equipment, better performance for corn glucose manufacturing plant.

Corn glucose manufacturing plant design

Currently, glucose syrup is mainly produced by first adding the enzyme α-amylase to a mixture of corn starch and water in corn glucose manufacturing plant. α-amylase is secreted by various species of the bacterium Bacillus; the enzyme is isolated from the liquid in which the bacteria are grown. The enzyme breaks the starch into oligosaccharides, which are then broken into glucose molecules by adding the enzyme glucoamylase, known also as "γ-amylase". Glucoamylase is secreted by various species of the fungus Aspergillus; the enzyme is isolated from the liquid in which the fungus is grown. The glucose can then be transformed into fructose by passing the glucose through a column that is loaded with the enzyme D-xylose isomerase, so except the glucose manufacturing plant, we also offer the high fructose corn syrup manufacturing plant.

Glucose manufacturing plant

Separation and purification:

After hydrolysis, the dilute syrup can be passed through ion exchange columns to remove impurities, improving its colour and stability.

Evaporation process in corn glucose manufacturing plant:

The dilute glucose syrup is finally evaporated under vacuum to raise the solids concentration.

Syrup evaporator

Compare the traditional technology, we supplied corn glucose manufacturing plant use double enzyme method can produce large range DE of glucose syrup for different application .

Our company supply the complete set corn glucose manufacturing plant with capacity from 10 ton per day to 200 ton per day. Our new technology of glucose manufacturing plant also can use rice flour as raw material to produce glucose syrup to make more big profit .

Plate frame filter press

The technology process of corn glucose manufacturing plant as below: extracting syrup from corns, enzymatic hydrolysis, chemical synthesis, separation and purification.Next will introduce DOING corn glucose manufacturing plant main process:

The starch needs to be swelled to allow the enzymes to act upon it. When grain is used, sulfur dioxide is added to prevent spoilage. By heating the ground, cleaned feedstock, starch gelatinization takes place: the intermolecular bonds of the starch molecules are broken down, allowing the hydrogen bonding sites to engage more water. This irreversibly dissolves the starch granule, so the chains begin to separate into an amorphous form. This prepares the starch can be used for hydrolysis. So actually this is the first step for corn glucose manufacturing plant process.

Hydrolysis by enzyme:

Glucose syrup can be produced by acid hydrolysis, enzyme hydrolysis, or a combination of the two. However, overall consideration, the enzyme hydrolysis is the best choice, no corrode the equipment, better performance for corn glucose manufacturing plant.

Corn glucose manufacturing plant design

Glucose manufacturing plant

After hydrolysis, the dilute syrup can be passed through ion exchange columns to remove impurities, improving its colour and stability.

Evaporation process in corn glucose manufacturing plant:

The dilute glucose syrup is finally evaporated under vacuum to raise the solids concentration.

Syrup evaporator

Compare the traditional technology, we supplied corn glucose manufacturing plant use double enzyme method can produce large range DE of glucose syrup for different application .

Our company supply the complete set corn glucose manufacturing plant with capacity from 10 ton per day to 200 ton per day. Our new technology of glucose manufacturing plant also can use rice flour as raw material to produce glucose syrup to make more big profit .

- Prev:Glucose fructose syrup production technology

- Next:Professional glucose fructose maltose syrup production line

Leave A Message About Corn glucose manufacturing plant

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- Liquid glucose plant production procedures are:starch mixing process,l...

- This is the glucose manufacturing plant main machine introduction,Doin...

- About the production of glucose in plants,Henan Doing Company can offe...

- Doing Company as one of glucose syrup making machine manufacturer with...

- To prepare glucose syrup, we need many kinds of glucose syrup preparat...

- To installed a liquid glucose syrup manufacturing plant,you clear abou...

- Cassava is a good raw material for starch production, and glucose syru...

- About the preparation of glucose syrup from starch, you need to prepar...

- Glucose fructose syrup production is a industry production, usually re...

- Professional corn glucose manufacturing plant introduction,corn glucos...