Glucose syrup making machine

Doing Company as one of glucose syrup making machine manufacturer with strong processing power, our glucose syrup making machine has been output to many areas, reach high reputation.

- Ms Elina Wu

- Phone:0086 135 2661 5783

- Email:sales@syrupmachine.com

Doing Company as one of glucose syrup making machine manufacturer with strong processing power, we have three factory, one main factory used for machines manufactur, other two little factory used for manufacturing spareparts. We are a professional glucose syrup making machine supplier in China, has been completed several project about glucose syrup making all over the world, received high reputation.

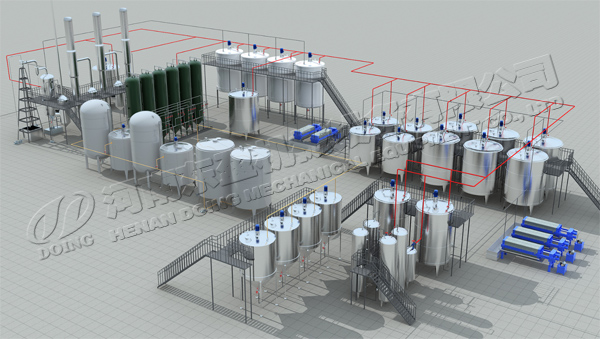

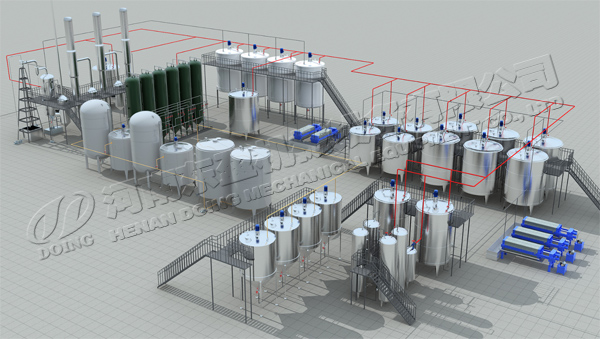

Below is the main glucose syrup making machine list view:

For another, about the glucose syrup making machine, you can see its actually a complete set of equipments used in plants, except above main machine, also many auxiliary equipment, on the following to introduce our glucose syrup making machine technology process for you:

DOING glucose syrup making machine

-1. Mixing and liquefaction:

(1) Mixing slurry: Add thermostable a-enzyme and water to starch, and mix them in mixing slurry tank, get a suitable slurry which is transparent and sticky.

(2) Spray liquefaction: Heating all tanks by steam, then open liquid ejectors and pumps, deliver material continuously and evenly, and control flow by production capacity. Flash evaporate material in Laminar flow tank, and keep temperature, observe liquefaction effect. After this liquefaction step processed by our glucose syrup making machine, adust the PH value to 4.4-4.5, then it can be prepared for glycosylated/ saccharification.

Mixing and liquefaction tank

(3) High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature.

(4) Carry slurry to buffer tank by pump. Mixing and iquefaction process is the first step of glucose syrup making machine.

-2. Filtration section during the glucose syrup making machine:

(1) Filter protein and slag by Plate-and-frame filter press machine.

(2) Carry away protein and slag by bottom slot. This is an add-value in your plant if you adopt our glucose syrup making machine, because the starch contain many protein, after filter, the protein cake will be a good source for animal feed.

(3) Syrup inflow buffer tanks, then be sent to next step by pump.

Saccharification tank

-3. Saccharification:

Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in saccharification tank) by pumps, then add glucoamylase.

-4. Decolorization by glucose syrup making machine:

Carry passed syrup into decolorization tanks(mixer and coil pipe are set in saccharification tank) by pump. Decolor by activated carbon added.

-5. Filtration process/ decarburization:

(1) Filter waste activated carbon by plate-and-frame filter press machine.

Plate and frame filter press machine

(2) Unclean syrup is sent to big buffer tanks by pump.

(3) Carry clean syrup into buffer tanks during our glucose syrup making machine process.

-6. Ion exchange section:

(1) Carry syrup into ion exchange columns. Resin clean syrup in ion exchange columns. Then carry clean syrup into buffer tanks.

(2) When resin loses effect of our glucose syrup making machine, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

Glucose syrup making machine

(3) Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till resin has function.

-7. Evaporation:

Evaporate syrup by Triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to storage tanks by pumps. You can click syrup evaporator to learn more details of our machine.

It's worth to say that the old technolgy of syrup production is using the corn starch as material, the newest technology in DOING of glucose syrup making machine can use the corn powder, rice powder/ broken rice as raw material, no need convert starch firslty, then been corn syrup, can be took of syrup from corns or maize. But if you use the potato, sweet potato, cassava, etc. as raw material to make glucose syrup, still need to procesed them into starch firstly.

Below is the main glucose syrup making machine list view:

| Machine | Model/ Volume |

| Mixing tank | volume 100L |

| Liquefaction tank | 24 m3 |

| Saccharification tank | 200 m3 |

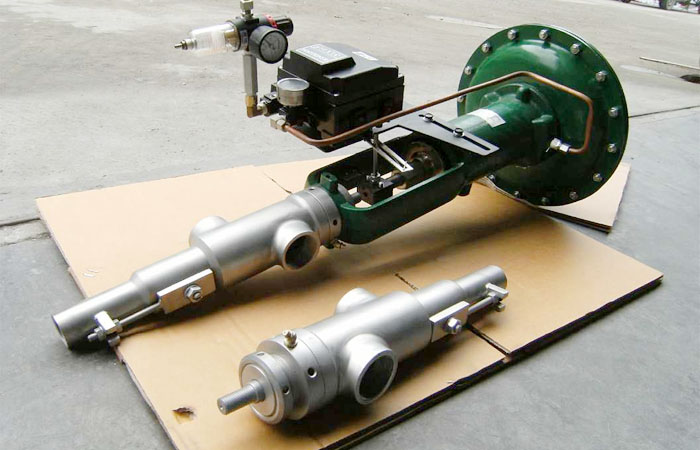

| Ejector | power 504 kw |

| Motor | power 840 kw |

| Ion exchange column | as requests |

| Filter press | 5000L/H |

| Vacuum cooler | volumn 12 m3 |

| Liquid-vapor seperator | volumn 12 m3 |

For another, about the glucose syrup making machine, you can see its actually a complete set of equipments used in plants, except above main machine, also many auxiliary equipment, on the following to introduce our glucose syrup making machine technology process for you:

DOING glucose syrup making machine

-1. Mixing and liquefaction:

(1) Mixing slurry: Add thermostable a-enzyme and water to starch, and mix them in mixing slurry tank, get a suitable slurry which is transparent and sticky.

(2) Spray liquefaction: Heating all tanks by steam, then open liquid ejectors and pumps, deliver material continuously and evenly, and control flow by production capacity. Flash evaporate material in Laminar flow tank, and keep temperature, observe liquefaction effect. After this liquefaction step processed by our glucose syrup making machine, adust the PH value to 4.4-4.5, then it can be prepared for glycosylated/ saccharification.

Mixing and liquefaction tank

(3) High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature.

(4) Carry slurry to buffer tank by pump. Mixing and iquefaction process is the first step of glucose syrup making machine.

-2. Filtration section during the glucose syrup making machine:

(1) Filter protein and slag by Plate-and-frame filter press machine.

(2) Carry away protein and slag by bottom slot. This is an add-value in your plant if you adopt our glucose syrup making machine, because the starch contain many protein, after filter, the protein cake will be a good source for animal feed.

(3) Syrup inflow buffer tanks, then be sent to next step by pump.

Saccharification tank

-3. Saccharification:

Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in saccharification tank) by pumps, then add glucoamylase.

-4. Decolorization by glucose syrup making machine:

Carry passed syrup into decolorization tanks(mixer and coil pipe are set in saccharification tank) by pump. Decolor by activated carbon added.

-5. Filtration process/ decarburization:

(1) Filter waste activated carbon by plate-and-frame filter press machine.

Plate and frame filter press machine

(2) Unclean syrup is sent to big buffer tanks by pump.

(3) Carry clean syrup into buffer tanks during our glucose syrup making machine process.

-6. Ion exchange section:

(1) Carry syrup into ion exchange columns. Resin clean syrup in ion exchange columns. Then carry clean syrup into buffer tanks.

(2) When resin loses effect of our glucose syrup making machine, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

Glucose syrup making machine

(3) Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till resin has function.

-7. Evaporation:

Evaporate syrup by Triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to storage tanks by pumps. You can click syrup evaporator to learn more details of our machine.

It's worth to say that the old technolgy of syrup production is using the corn starch as material, the newest technology in DOING of glucose syrup making machine can use the corn powder, rice powder/ broken rice as raw material, no need convert starch firslty, then been corn syrup, can be took of syrup from corns or maize. But if you use the potato, sweet potato, cassava, etc. as raw material to make glucose syrup, still need to procesed them into starch firstly.

Leave A Message About Glucose syrup making machine

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- Liquid glucose plant production procedures are:starch mixing process,l...

- This is the glucose manufacturing plant main machine introduction,Doin...

- About the production of glucose in plants,Henan Doing Company can offe...

- Doing Company as one of glucose syrup making machine manufacturer with...

- To prepare glucose syrup, we need many kinds of glucose syrup preparat...

- To installed a liquid glucose syrup manufacturing plant,you clear abou...

- Cassava is a good raw material for starch production, and glucose syru...

- About the preparation of glucose syrup from starch, you need to prepar...

- Glucose fructose syrup production is a industry production, usually re...

- Professional corn glucose manufacturing plant introduction,corn glucos...