Glucose syrup is a syrup made from the hydrolysis of starch. Glucose is a sugar. Maize (corn) is commonly used as the source of the starch, in which case the syrup is called "corn syrup", but glucose syrup is also can made from potatoes and wheat starch.

Slurry processes (batter processes) are more industry friendly and make closed continuous handling possible. Several variants have been practiced over time, but the DOING Process is by far the most elegant and efficient.

Based on wheat starch as raw material for how glucose syrup made from wheat

Wheat starch is pneumatically conveyed from intermediate silos into a feeding bin equipped with means to separate air and flour. The control system continuously discharges wheat starch into a stream of warm water. Water and flour is mixed in-line and the slurry obtained is homogenized in a high-speed in-line disintegrator.

Made glucose syrup from wheat

The starch fraction is the heavy phase containing the major part of A-starch. It is re-slurred and refined - much in the same way as starch of any other origin as described in "Starch Refining". The gluten fraction is the complex middle phase. It contains the gluten, fibres, solubles, B-starch and some A-starch. After maturing of the gluten these constituents are split into sub-fractions.

Gluten Maturing. Before separating the gluten fraction the stream is carefully treated in a maturing reactor. The reactor is specially designed for the maturing of gluten. During maturing the “gluten matrix” of wheat flour is softened and bound starch granules are released in the process for how glucose syrup made from wheat. Glutenin and gliadin proteins can now start to form long molecular chains i.e. gluten formation can take place.

Gluten Agglomeration and Recovery. The gluten maturing step is followed by a treatment in special gluten agglomerators.

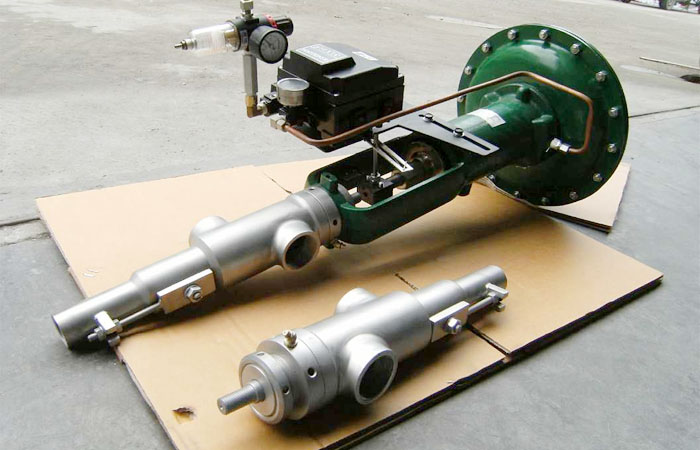

Glucose syrup production equipment

In the agglomerators the matured gluten is combined into lumps formed of glutenin and gliadin. The gluten lumps are screened off and washed on bend screens.

The wet gluten is dewatered on screw presses and dried. By gentle drying in hot air in a ring dryer the gluten retains its vital properties. After in-line milling and classification the product leaves the dryer ready for packing and sale as Vital Gluten, this is an add-value of how glucose syrup made from wheat.

B-starch recovery. After gluten recovery the residual fraction is separated on hydrocyclones. The heavy A-starch goes in the underflow and the lighter B-starch goes with the overflow.

A-starch recovered with the underflow is concentrated and combined with the A-starch main stream.

B-starch is recovered from the overflow by special recovery cyclones and dewatered on a decanter. The B-starch is dried in hot air in a ring dryer or drum dried and used as pre-gelatinized starch.

Glucose syrup production plant

Solubles. A clarifier removes the last bit of starch from the overflow and only solubles and water remains. The clarified overflow leaves the factory as an effluent to be disposed of by landspreading or biogas digestion. In fact, among is the wheat starch extraction process for how glucose syrup made from wheat, and you can see that our processing way is reasonable, high raw material using rate.

STARCH REFINING of how glucose syrup made from wheat:

Starch is refined by washing with fresh clean water. With hydrocyclones it is feasible to reduce fibre and solubles including soluble protein to low levels with a minimum of fresh water. To save water the wash is done counter currently, i.e. the incoming fresh water is used on the very last step and the overflow is reused for dilution on the previous step, and so on.

By using multi stage hydrocyclones all soluble materials and fine cell residues are removed in a water saving process. The refined starch milk contains an almost 100% pure starch slurred in pure water.

Starch is among the most pure of all agricultural products. Actually, purity is the most important parameter in being competitive, also an important factor to influencing the finished products quality for how glucose syrup made from wheat.

Glucose syrup production equipment

Then use A-starch milk to continuous spray liquefaction section. Starch milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme.

Then saccharification: The liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme.

After that, it is filtration and decolorization process: Glucose gets through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

Finally evaporation: The glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product.

Slurry processes (batter processes) are more industry friendly and make closed continuous handling possible. Several variants have been practiced over time, but the DOING Process is by far the most elegant and efficient.

Based on wheat starch as raw material for how glucose syrup made from wheat

Wheat starch is pneumatically conveyed from intermediate silos into a feeding bin equipped with means to separate air and flour. The control system continuously discharges wheat starch into a stream of warm water. Water and flour is mixed in-line and the slurry obtained is homogenized in a high-speed in-line disintegrator.

Made glucose syrup from wheat

The starch fraction is the heavy phase containing the major part of A-starch. It is re-slurred and refined - much in the same way as starch of any other origin as described in "Starch Refining". The gluten fraction is the complex middle phase. It contains the gluten, fibres, solubles, B-starch and some A-starch. After maturing of the gluten these constituents are split into sub-fractions.

Gluten Maturing. Before separating the gluten fraction the stream is carefully treated in a maturing reactor. The reactor is specially designed for the maturing of gluten. During maturing the “gluten matrix” of wheat flour is softened and bound starch granules are released in the process for how glucose syrup made from wheat. Glutenin and gliadin proteins can now start to form long molecular chains i.e. gluten formation can take place.

Gluten Agglomeration and Recovery. The gluten maturing step is followed by a treatment in special gluten agglomerators.

Glucose syrup production equipment

In the agglomerators the matured gluten is combined into lumps formed of glutenin and gliadin. The gluten lumps are screened off and washed on bend screens.

The wet gluten is dewatered on screw presses and dried. By gentle drying in hot air in a ring dryer the gluten retains its vital properties. After in-line milling and classification the product leaves the dryer ready for packing and sale as Vital Gluten, this is an add-value of how glucose syrup made from wheat.

B-starch recovery. After gluten recovery the residual fraction is separated on hydrocyclones. The heavy A-starch goes in the underflow and the lighter B-starch goes with the overflow.

A-starch recovered with the underflow is concentrated and combined with the A-starch main stream.

B-starch is recovered from the overflow by special recovery cyclones and dewatered on a decanter. The B-starch is dried in hot air in a ring dryer or drum dried and used as pre-gelatinized starch.

Glucose syrup production plant

STARCH REFINING of how glucose syrup made from wheat:

Starch is refined by washing with fresh clean water. With hydrocyclones it is feasible to reduce fibre and solubles including soluble protein to low levels with a minimum of fresh water. To save water the wash is done counter currently, i.e. the incoming fresh water is used on the very last step and the overflow is reused for dilution on the previous step, and so on.

By using multi stage hydrocyclones all soluble materials and fine cell residues are removed in a water saving process. The refined starch milk contains an almost 100% pure starch slurred in pure water.

Starch is among the most pure of all agricultural products. Actually, purity is the most important parameter in being competitive, also an important factor to influencing the finished products quality for how glucose syrup made from wheat.

Glucose syrup production equipment

Then saccharification: The liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme.

After that, it is filtration and decolorization process: Glucose gets through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

Finally evaporation: The glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product.

Leave A Message About How glucose syrup made from wheat ?

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...