How does syrup produced? Usually the best raw material is starch powder because of its free of protein and fats etc. Essentially glucose production is the process of starch hydrolysis by effect of enzyme.

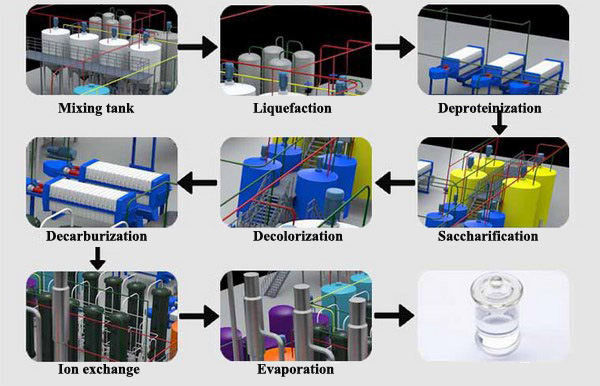

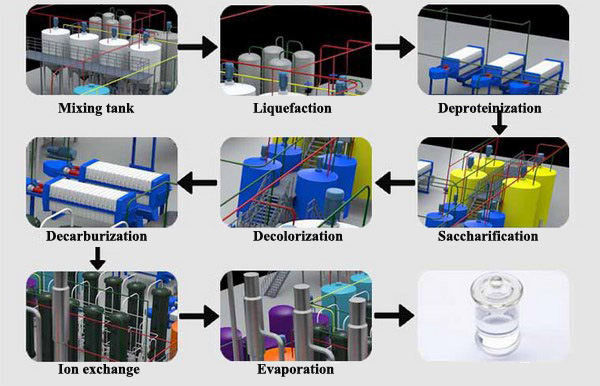

How does syrup produced from starch? The procedures can be divided into five main sections: liquefaction, saccharification, decoloration, ion exchange and evaporation. Detailed introduction of each section as bellow:

Syrup production process

I. Liquefaction process:

After starch mixed with water, pump starch slurry into the liquefaction tank. By the effect of jet cooker, the temperature increase quickly. Starch granule absorb water and swell, then the liquid becomes transparent paste from suspension liquid for how does syrup produced, which is called gelatinization that provides better environment for liquefaction enzyme. Then keep temperature around 95℃ for certain time, to make liquefaction finished completely.

II. Saccharification process:

Liquid from liquefaction process is called dextrin. Before saccharification process, filter press will be used to remove protein and solid impurities from liquid dextrin. After deproteinization, liquid dextrin will be pumped into saccharification tanks for the process of how does syrup produced.

The saccharification process is actually providing an environment that is suitable for saccharification enzymes, mainly the adjustment of pH and temperature. The liquid dextrin is first adjusted with acid to adjust the pH, and then cooled down by using cooling water to obtain a suitable temperature in the processing of how does syrup produced. Finally, the saccharification enzyme is used to complete the liquefaction solution. The final hydrolysis of the sugar gives crude glucose solution.

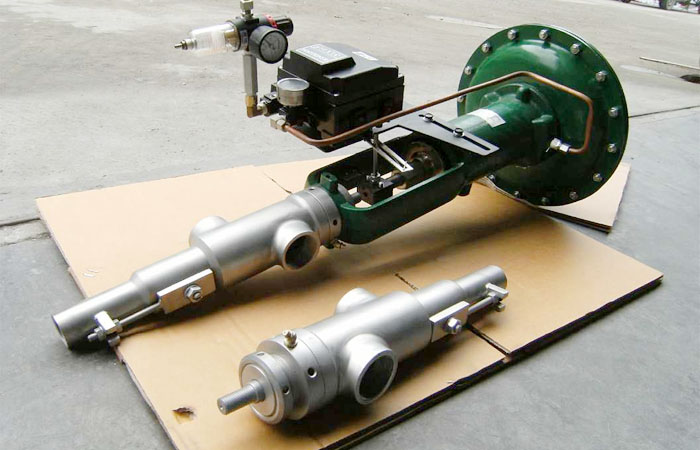

Syrup production equipments

III. Decoloration process:

The normal sequence of decoloration is: 1st decolorization→ 1st decarburization→2nd decolorization→2nd decarburization.

The saccharification liquid will be pumped into a decolorization tank for how does syrup produced, adding the waste activated carbon of the second plate frame filter pressing then killing enzyme and decolorization for 30 minutes. Then pumping the discolored syrup liquid into the first syrup filter machine press, the activated carbon will be filter out. Pumping the first discolored syrup liquid into the second decolorization tank, adding new activated carbon, decolorization for 30 minutes. The second decolored syrup liquid is subjected to plate and frame filtration, and then it will be pumped into the ion exchange system storage tank through the plate heat exchanger.

IV. Ion exchange process:

This part in the processing of how does syrup produced aims to remove the impurities and different ions to ensure the purity of syrup. Normally, it needs the anion-cation process, pump the discolored syrup liquid into the storage tank, keep the temperature about 30 ℃, and then pump the liquid syrup into the cation exchange column to remove the Ca2+ and Mg2+ etc; and then pump syrup into the cathode column to remove the negative ions. Finally pump the syrup into the adjusting pillars for conductance and pH adjustment.

Resin Regeneration: After soaking resin for a certain time, open all the valve, start the deionized water pump to wash resin. At start control the water flow in small volume and increase volume after acid (or alkali) washed out.

Syrup production plant overview

V. Evaporation:

After ion exchange, the syrup will be pumped into the storage tank for how does syrup produced, after heating exchange and then enter into the syrup evaporator. Evaporator consists of single-effect evaporator and multi-effect evaporator. Usually three-effect evaporator is applied, which can make full use of steam and save energy consumption. The first effect evaporator vacuum degree is 0.01-0.03Mpa, the temperature is about 105 ℃, the second-effect evaporator vacuum degree is 0.015-0.028Mpa, the temperature is 84 ℃ -90 ℃, the third-effect evaporation vacuum degree is 0.04-0.05Mpa, the temperature is 55 ℃ -60 ℃ etc. After evaporation, DS value is between 75-85%, which can be adjusted according to user's requirements.

Finally, our syrup machine and technology method can used for glucose syrup, high fructose corn syrup and maltose syrup production, any other questions or details for how does syrup produced, contact us freely.

How does syrup produced from starch? The procedures can be divided into five main sections: liquefaction, saccharification, decoloration, ion exchange and evaporation. Detailed introduction of each section as bellow:

Syrup production process

After starch mixed with water, pump starch slurry into the liquefaction tank. By the effect of jet cooker, the temperature increase quickly. Starch granule absorb water and swell, then the liquid becomes transparent paste from suspension liquid for how does syrup produced, which is called gelatinization that provides better environment for liquefaction enzyme. Then keep temperature around 95℃ for certain time, to make liquefaction finished completely.

II. Saccharification process:

Liquid from liquefaction process is called dextrin. Before saccharification process, filter press will be used to remove protein and solid impurities from liquid dextrin. After deproteinization, liquid dextrin will be pumped into saccharification tanks for the process of how does syrup produced.

The saccharification process is actually providing an environment that is suitable for saccharification enzymes, mainly the adjustment of pH and temperature. The liquid dextrin is first adjusted with acid to adjust the pH, and then cooled down by using cooling water to obtain a suitable temperature in the processing of how does syrup produced. Finally, the saccharification enzyme is used to complete the liquefaction solution. The final hydrolysis of the sugar gives crude glucose solution.

Syrup production equipments

III. Decoloration process:

The normal sequence of decoloration is: 1st decolorization→ 1st decarburization→2nd decolorization→2nd decarburization.

The saccharification liquid will be pumped into a decolorization tank for how does syrup produced, adding the waste activated carbon of the second plate frame filter pressing then killing enzyme and decolorization for 30 minutes. Then pumping the discolored syrup liquid into the first syrup filter machine press, the activated carbon will be filter out. Pumping the first discolored syrup liquid into the second decolorization tank, adding new activated carbon, decolorization for 30 minutes. The second decolored syrup liquid is subjected to plate and frame filtration, and then it will be pumped into the ion exchange system storage tank through the plate heat exchanger.

IV. Ion exchange process:

This part in the processing of how does syrup produced aims to remove the impurities and different ions to ensure the purity of syrup. Normally, it needs the anion-cation process, pump the discolored syrup liquid into the storage tank, keep the temperature about 30 ℃, and then pump the liquid syrup into the cation exchange column to remove the Ca2+ and Mg2+ etc; and then pump syrup into the cathode column to remove the negative ions. Finally pump the syrup into the adjusting pillars for conductance and pH adjustment.

Resin Regeneration: After soaking resin for a certain time, open all the valve, start the deionized water pump to wash resin. At start control the water flow in small volume and increase volume after acid (or alkali) washed out.

Syrup production plant overview

V. Evaporation:

After ion exchange, the syrup will be pumped into the storage tank for how does syrup produced, after heating exchange and then enter into the syrup evaporator. Evaporator consists of single-effect evaporator and multi-effect evaporator. Usually three-effect evaporator is applied, which can make full use of steam and save energy consumption. The first effect evaporator vacuum degree is 0.01-0.03Mpa, the temperature is about 105 ℃, the second-effect evaporator vacuum degree is 0.015-0.028Mpa, the temperature is 84 ℃ -90 ℃, the third-effect evaporation vacuum degree is 0.04-0.05Mpa, the temperature is 55 ℃ -60 ℃ etc. After evaporation, DS value is between 75-85%, which can be adjusted according to user's requirements.

Finally, our syrup machine and technology method can used for glucose syrup, high fructose corn syrup and maltose syrup production, any other questions or details for how does syrup produced, contact us freely.

Leave A Message About How does syrup produced ?

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...