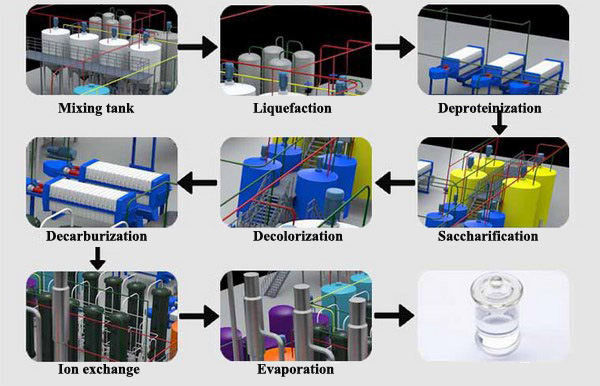

About the question how to make glucose syrup, except the glucose syrup making technology, also need a complete set of glucose syrup making equipments, following is the technology process of how to make glucose syrup:

1. Mixing the starch with water to get starch milk.

2. Liquefaction system to get slurry of glucose syrup making.

3. Saccharification by saccharifying tank.

4. Saccharification liquid discoloration, and filtration process.

5. Ion exchange to get very pure glucose syrup.

6. Used multiple-effect evaporator for glucose syrup evaporation and concentration.

7. Offer professional glucose syrup storage tank, easily for the further package and shippment.

Glucose syrup making process

For the first, we all know the liquefaction and saccharification process is the basic of how to make glucose syrp, high influenced for the final glucose syrup quality. In the answer for how to make glucose syrup, hydrolysis of starch is finished by liquefaction and saccharification. In liquefaction process, starch granule firstly absorb water and swell during heating procedure, volume increases rapidly and crystal structure is broken. Then starch milk becomes kind of trick liquid, which is known as gelatinization. Gelatinization is first part of liquefaction. After gelatinization, starch granule structure is broken and is exposed to enzyme directly. Molecular chain of starch granule is disconnected quickly and becomes dextrin. This is the whole process of liquefaction. For how to make glucose syrup, saccharification process is to make dextrin into glucose. It is finished by effect of saccharifying enzyme. Enzyme reaction speed and process can be controlled by adjusting enzyme amount and reaction time. Required starch syrup could be obtained through the enzyme controlling process.

Liquefaction and saccharification process technical parameters:

Secondly, Doing Company is a professional glucose syrup making equipments manufacturer, we own the advanced technology of the glucose making, adopt double-enzyme method. About the answer for how to make glucose syrup, you need to prepare whole set of glucose syrup equipment, raw material(you can click the link to learn about the raw material of glucose syrup making), and have to know the technology. Doing Company complete set of glucose syrup equipment is an ideal choice, good reputation from our clients home and abroad.

Doing Company glucose syrup making equipments

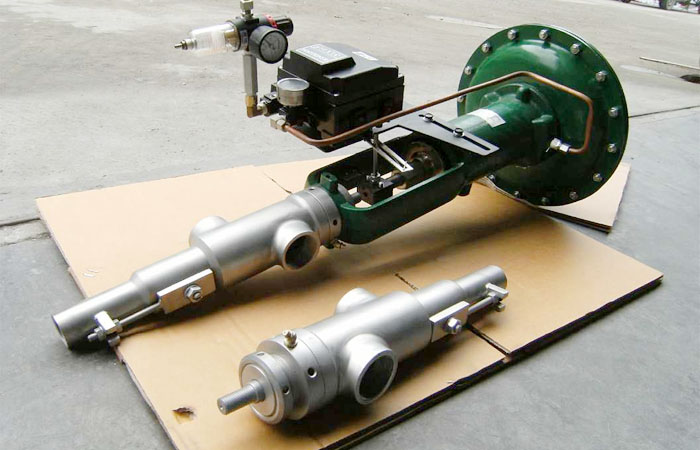

The main Doing Company equipment of how to make glucose syrup include mixing tank, underflow pump, ejector, high temperature maintenance tank, flash tank, centrifugal pump, saccharifying tank, bleaching tank, plate and frame filter press. The production process is: starch mixing with water(first time add enzyme), liquefacation process, high temperature maintenance, flash cooling(second time add α-enzyme), saccharificance process(used glucoamylase), enzyme deactivation process, bleaching process, filter and evaporation.

All main equipments used to make glucose syrup

Doing factory glucose syrup making equipment features:

1. Dry method directly used raw grains to make pure and bright glucose syrup.

2. No polluted water, environmental protection.

3. Advanced and high quality jet cooker, improve the efficiency and quality of liquefication and saccharification process.

4. One set syrup equipment can product three syrup: glucose syrup, maltose syrup and fructose syrup.

5. We have different size syrup equipment, can meet all kinds of capacity requests. 3-5ton, 10-20ton, 30-50ton, 50-100ton per day, all is a complete production line.

Doing Company also can make solutions and turn-key project for you. Perfect service for you to answer your question how to make glucose syrup.

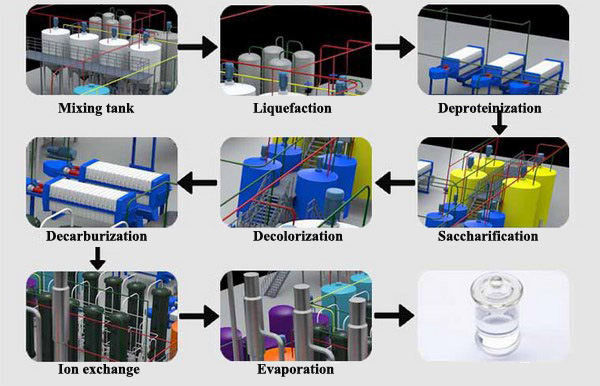

1. Mixing the starch with water to get starch milk.

2. Liquefaction system to get slurry of glucose syrup making.

3. Saccharification by saccharifying tank.

4. Saccharification liquid discoloration, and filtration process.

5. Ion exchange to get very pure glucose syrup.

6. Used multiple-effect evaporator for glucose syrup evaporation and concentration.

7. Offer professional glucose syrup storage tank, easily for the further package and shippment.

Glucose syrup making process

For the first, we all know the liquefaction and saccharification process is the basic of how to make glucose syrp, high influenced for the final glucose syrup quality. In the answer for how to make glucose syrup, hydrolysis of starch is finished by liquefaction and saccharification. In liquefaction process, starch granule firstly absorb water and swell during heating procedure, volume increases rapidly and crystal structure is broken. Then starch milk becomes kind of trick liquid, which is known as gelatinization. Gelatinization is first part of liquefaction. After gelatinization, starch granule structure is broken and is exposed to enzyme directly. Molecular chain of starch granule is disconnected quickly and becomes dextrin. This is the whole process of liquefaction. For how to make glucose syrup, saccharification process is to make dextrin into glucose. It is finished by effect of saccharifying enzyme. Enzyme reaction speed and process can be controlled by adjusting enzyme amount and reaction time. Required starch syrup could be obtained through the enzyme controlling process.

Liquefaction and saccharification process technical parameters:

| Liquefaction | Starch slurry concentration | 32%-36% |

| α-enzyme | 8-10/ ton starch | |

| PH value | 6.0-6.4 | |

| DE value | 15%-20% | |

| Saccharification | Glucomylase | 0.45-0.58L/ ton starch |

| PH value | 5.5 | |

| DE value | 95%-98% |

Secondly, Doing Company is a professional glucose syrup making equipments manufacturer, we own the advanced technology of the glucose making, adopt double-enzyme method. About the answer for how to make glucose syrup, you need to prepare whole set of glucose syrup equipment, raw material(you can click the link to learn about the raw material of glucose syrup making), and have to know the technology. Doing Company complete set of glucose syrup equipment is an ideal choice, good reputation from our clients home and abroad.

Doing Company glucose syrup making equipments

The main Doing Company equipment of how to make glucose syrup include mixing tank, underflow pump, ejector, high temperature maintenance tank, flash tank, centrifugal pump, saccharifying tank, bleaching tank, plate and frame filter press. The production process is: starch mixing with water(first time add enzyme), liquefacation process, high temperature maintenance, flash cooling(second time add α-enzyme), saccharificance process(used glucoamylase), enzyme deactivation process, bleaching process, filter and evaporation.

All main equipments used to make glucose syrup

Doing factory glucose syrup making equipment features:

1. Dry method directly used raw grains to make pure and bright glucose syrup.

2. No polluted water, environmental protection.

3. Advanced and high quality jet cooker, improve the efficiency and quality of liquefication and saccharification process.

4. One set syrup equipment can product three syrup: glucose syrup, maltose syrup and fructose syrup.

5. We have different size syrup equipment, can meet all kinds of capacity requests. 3-5ton, 10-20ton, 30-50ton, 50-100ton per day, all is a complete production line.

Doing Company also can make solutions and turn-key project for you. Perfect service for you to answer your question how to make glucose syrup.

Leave A Message About How to make glucose syrup ?

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...