In a continuous process for the industrial production of high fructose corn syrup, corn syrup containing glucose is passed through a reactor containing a solid phase enzyme to convert about half of the glucose into fructose.

Industrial production of high fructose corn syrup made in the professional factory, processed by the professional syrup equipment and equipped with advanced technology, capacity is large. Nowadays, the enzymatic method is the most efficient choice used for the industrial production of high fructose corn syrup, finished syrup high quality, high purity, sufficient hydrolysis of starch. Finished high fructose corn syrup are mainly used in the food and beverage processing factory.

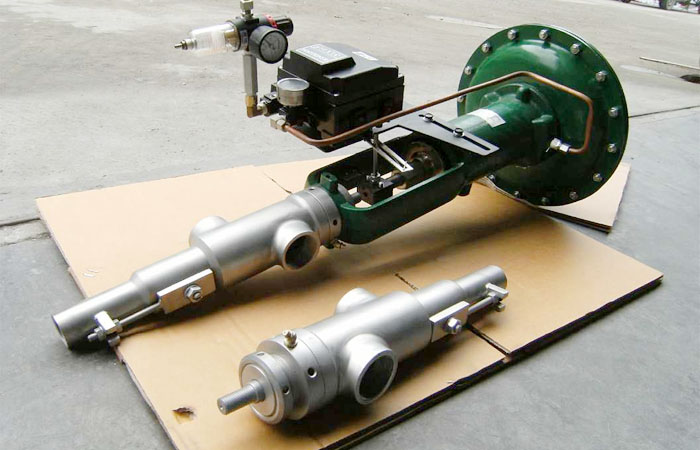

High fructose corn syrup production equipments

High fructose corn syrup industrial production is according to the starch processed by enzymatic method to get saccharification liquid, then part of glucose processed by isomerism system change to fructose, that is to say the high fructose corn syrup is a mixture of glucose and fructose. In the industrial production of high fructose corn syrup, to get more sweetness products, usually filter the glucose, then make isomerism process repeatedly to change more glucose into fructose, impove the fructose content. High fructose corn syrup can substitute sugar to used in food and beverage industry, with more advantages, the cost is lower than sugar, but flavor and taste is better. High fructose corn syrup industrial production process is: mixing and liquidation - saccharify - liquid syrup decolorizing - filtration - ion exchange - isomerism system - syrup refined - F42 high fructose syrup. It's worth to say that you can futher process the F42 high fructose corn syrup to get F90, and get F55 from mixing the F42 and F90.

There are two basic principles of enzyme technology for the industrial production of high fructose corn syrup:

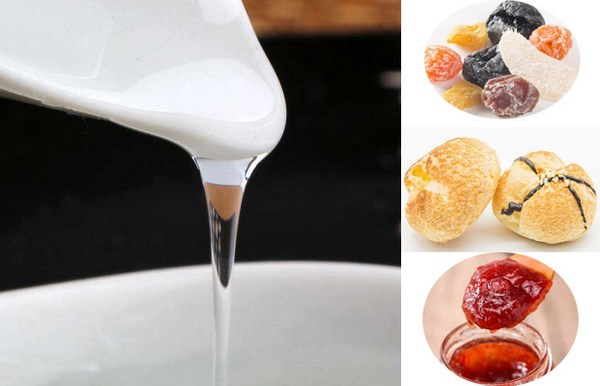

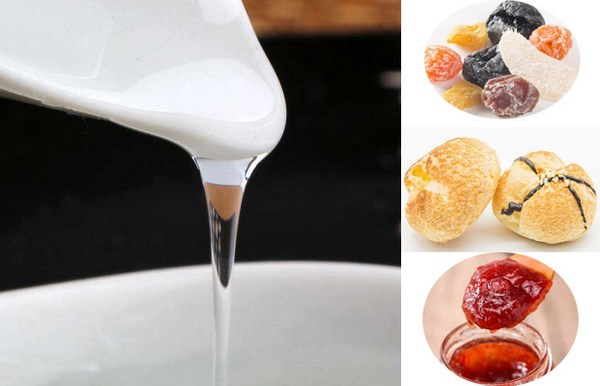

High fructose corn syrup used for food industry

1. The sugar mold is cultivated under deep aeration conditions. The fermented mash of the can is adjusted to pH and heated to fix the glucose isomerase in the bacteria for industrial production of high fructose corn syrup. Filter and wash with water. The filter cake is dried and pumped into a pressurized blade filter with a mixture of glucose, MgSO4 and NaHSO3 containing corn starch hydrolysate until each leaf is coated with a solid phase enzyme preparation having a thickness of 2.54 to 3.81 cm. The filter acts as a reactor.

2. Glucose isomerase is adsorbed onto DEAE----cellulose or other adsorbent. This powder is filtered on a pressurized vane filter which acts as a reactor. Corn syrup was pumped into the reactor to control the flow rate to 45% glucose conversion to the sugar. When the activity of the solid phase isomerase preparation is gradually decreased, the flow rate is gradually reduced, so that glucose still has 45% of the converted sugar.

Machines used for industrial production of high fructose corn syrup from Doing Company main contain mixing tank, jet cooker, liquefaction tank, saccharification tank, plate frame filter press, ion exchange column, isomerism column, syrup evaporator, and other auxiliary equipment, conveyor, etc.

Industrial production of high fructose corn syrup made in the professional factory, processed by the professional syrup equipment and equipped with advanced technology, capacity is large. Nowadays, the enzymatic method is the most efficient choice used for the industrial production of high fructose corn syrup, finished syrup high quality, high purity, sufficient hydrolysis of starch. Finished high fructose corn syrup are mainly used in the food and beverage processing factory.

High fructose corn syrup production equipments

There are two basic principles of enzyme technology for the industrial production of high fructose corn syrup:

High fructose corn syrup used for food industry

2. Glucose isomerase is adsorbed onto DEAE----cellulose or other adsorbent. This powder is filtered on a pressurized vane filter which acts as a reactor. Corn syrup was pumped into the reactor to control the flow rate to 45% glucose conversion to the sugar. When the activity of the solid phase isomerase preparation is gradually decreased, the flow rate is gradually reduced, so that glucose still has 45% of the converted sugar.

Machines used for industrial production of high fructose corn syrup from Doing Company main contain mixing tank, jet cooker, liquefaction tank, saccharification tank, plate frame filter press, ion exchange column, isomerism column, syrup evaporator, and other auxiliary equipment, conveyor, etc.

Leave A Message About Industrial production of high fructose corn syrup

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...