Corn syrup processing plant

As for the corn syrup processing plant, What we used is the two-enzyme method to process corn syrup. That means when liquefaction and saccharification section, we will put different ensymes to ensure the final product is corn syrup.

- Ms Elina Wu

- Phone:0086 135 2661 5783

- Email:sales@syrupmachine.com

Corn syrup is a food syrup which is made from the starch of corn and contains varying amounts of maltose and higher oligosaccharides, depending on the grade. As for the corn syrup processing plant production technology, What we used is the two-enzyme method to process corn syrup from corn starch. That means when liquefaction and saccharification section, we will put different enzymes to ensure the final product is high quality corn syrup. Below is the detailed process description of corn syrup processing plant:

Syrup produce from corn

1st step Mixing Slurry:

Put the corn starch powder and certain water into the mixing tank in corn syrup processing plant, then put in enzyme, keep on particular standard temperature and PH value as specified, waiting for some time, then transport to next work section.

2nd step Injector Liquefaction

The mixed corn starch powder milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme at high temperature in regular time for corn syrup processing plant liquefaction process.

3rd step Filter Press Deproteinization

Because of inside of the corn starch slurry contains a certain percentage of protein, so the slurry need pumping into the press filter for corn syrup processing plant processing, after press the slurry, the syrup will flow into the slot for next saccharification process, the protein will stay inside the filter machine and then discharged for sale.

Put the corn starch powder and certain water into the mixing tank in corn syrup processing plant, then put in enzyme, keep on particular standard temperature and PH value as specified, waiting for some time, then transport to next work section.

2nd step Injector Liquefaction

The mixed corn starch powder milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme at high temperature in regular time for corn syrup processing plant liquefaction process.

3rd step Filter Press Deproteinization

Because of inside of the corn starch slurry contains a certain percentage of protein, so the slurry need pumping into the press filter for corn syrup processing plant processing, after press the slurry, the syrup will flow into the slot for next saccharification process, the protein will stay inside the filter machine and then discharged for sale.

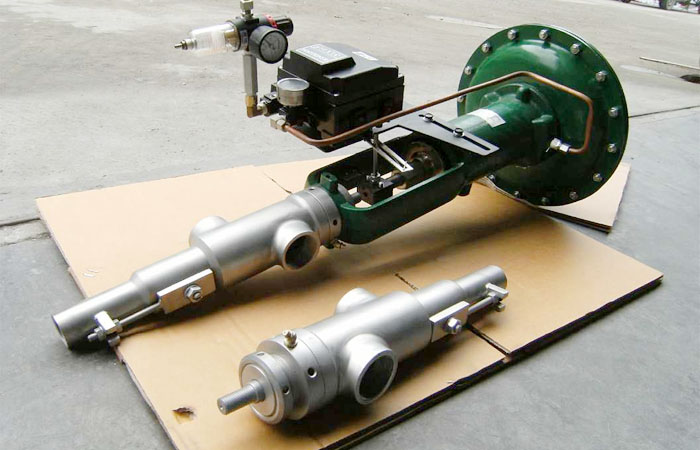

Corn syrup processing equipment

4th step Saccharification in corn syrup processing plant:

The liquefied material is sent to enzyme saccharification tank for reaction. Maintain at specific temperature for some time, the syrup will transfer to glucose syrup with the required DE value .

5th step Decolorization:

After LAB testing in corn syrup processing plant, that make sure we have got required DE value syrup, all the glucose syrup is pumped into the decoloration tanks, at uniform temperature, put in the activated carbon mixing with the glucose syrup, usually have to make twice to get pure glucose syrup.

6th step Filter Press Decarburization

The glucose syrup with activated carbon will be pumped into the press filter, after press the clean glucose syrup will flow into the buffer tank, the activated carbon will stay inside the filter and then discharged outside in corn syrup processing plant.

DOING ion exchange column

7th step Ion Exchange

The clean glucose syrup pumping into the ion exchange columns, inside the column resin will attract all the cation and anion and other small electron, then will get very pure glucose syrup for people eating. This equipment always is used for high quality syrup produce in corn syrup processing plant.

8th step Evaporation process:

The pure and clean corn syrup have very low density, the triple effect evaporator can evaporate frucotse inside water to outside increase density at very short time. Then pump the corn syrup into the single-concentrate of evaporator continue evaporate water for concentrating to reach the required DS as final product corn syrup in corn syrup processing plant.

The clean glucose syrup pumping into the ion exchange columns, inside the column resin will attract all the cation and anion and other small electron, then will get very pure glucose syrup for people eating. This equipment always is used for high quality syrup produce in corn syrup processing plant.

8th step Evaporation process:

The pure and clean corn syrup have very low density, the triple effect evaporator can evaporate frucotse inside water to outside increase density at very short time. Then pump the corn syrup into the single-concentrate of evaporator continue evaporate water for concentrating to reach the required DS as final product corn syrup in corn syrup processing plant.

Corn syrup processing plant

To sum up, corn syrup production steps can be divided into three parts: starch hydrolysis and sugar production, impurities removing, evaporate water and get required DS value syrup.

- Prev:Complete set stainless steel rice glucose syrup production equipment

- Next:High fructose rice syrup production line

Leave A Message About Corn syrup processing plant

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- In the high fructose corn syrup factory, to produce fructose, firstly ...

- Fructose syrup preparation machine used for fructose syrup productioni...

- The introduction of the fructose syrup production machineand its funct...

- The glucose fructose syrup production machine actually consists of the...

- Use the starch for example to introduce the F42 high fructose corn syr...

- High fructose syrup production is according to the starch processed by...

- High fructose syrup production process contain: mixing and liquidatio...

- we can provide you the different capacity corn syrup production proces...

- Above all is the description for high fructose corn syrup manufacturin...

- My company is very professional in manufacturing the complete high fru...