F42 high fructose corn syrup manufacturing process

Use the starch for example to introduce the F42 high fructose corn syrup manufacturing process. High fructose corn syrup manufacturing process include starch liquefaction, saccharification and isomerism process.

- Ms Elina Wu

- Phone:0086 135 2661 5783

- Email:sales@syrupmachine.com

Fructose corn syrup also called high fructose corn syrup or isomer syrup. F42 high fructose corn syrup also called as standard fructose corn syrup, Its process mainly raw material is starch, F42 high fructose corn syrup manufacturing process is according to the enzyme method to saccharify starch, then the saccharification solution under the isomerism enzyme process change the glucose into fructose. For another, you can click the link: the raw material to manufacturing high fructose corn syrup to learn about the raw material preparation for F42 high fructose corn syrup manufacturing process.

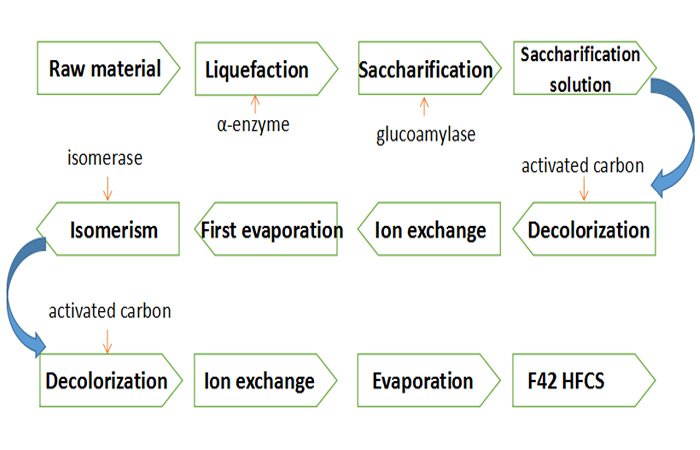

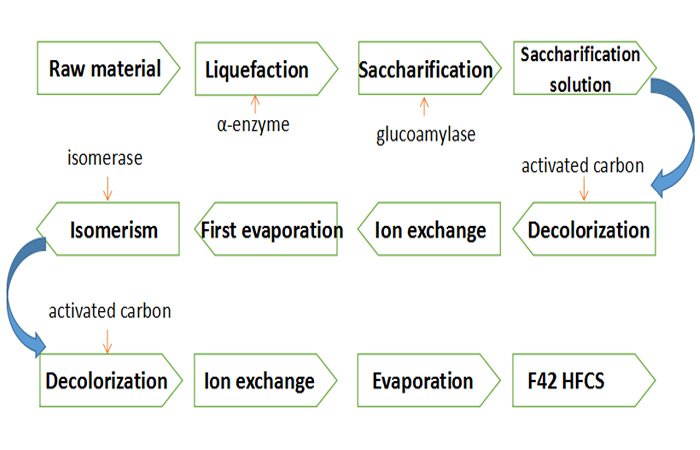

On the following use the starch for example to introduce the F42 high fructose corn syrup manufacturing process. High fructose corn syrup manufacturing process include starch liquefaction, saccharification and isomerism process. The manufacturing process flowchart as below:

F42 high fructose corn syrup manufacturing process

Liquefaction:

Starch slurry mixed with 30-35% dry solids and adjust its PH value to 6.0-6.4. Before put into α-enzyme, first add calcium, because calcium ions can stabilize the enzyme. Then mixed heat-stable α-enzyme (Novo’s Termamyl 120L) into the starch slurry, the slurry is instantaneously heated to 100 ℃ and held at this temperature for 10 min before it is cooled to 90 ℃. This temperature is maintained for 1-3h service for further hydrolyze the starch. Among this, it is the liquefaction process introduction in the F42 high fructose corn syrup manufacturing process.

Liquefaction process technical parameters:

After this liquefying process complete in the F42 high fructose corn syrup manufacturing process, the starch has been transfered into dextrins with a dextrose equivalent (DE) between 15 and 20. (The physical properties of the syrup changed with the DE and the method of manufacture difference.) DE is the total reducing sugar in the syrup expressed as dextrose on a dry weight basis.

Doing Company high fructose corn syrup manufacturing process main equipments

Saccharification:

After liquefaction, the pH is reduced to between 4.2 and 4.5 and after the solution is cooled to 60 ℃. A glucomylase (Novo’s AMG 300L) is added immediately. The reaction time for saccharification is usually between 24-48 hour depending on enzyme reaction. Glucoamylase releases single glucose units from the ends of dextrin molecule. Syrups of 95% glucose or higher are manufactured. This is the saccharification process for the F42 high fructose corn syrup manufacturing process.

Saccharification process technical paramters:

It's worth to tell you the liquefaction and saccharification step is the most important two parts of the F42 high fructose corn syrup manufacturing process from glucose. These steps performance influenced the glucose products quality directly. So the advanced technology and equipments select for the F42 high fructose corn syrup manufacturing process is very important.

Doing Company syrup equipments plant

Isomerism:

The purified glucose solution is isomerized by a reactor containing immobilized isomerase to obtain fructose syrup with 42% fructose content. It's honor to tell you that the isomerase we are using is a kind of immobilized enzyme. Converted from soluble state into immobilized state, the stability of isomerism will be increased significantly and it can be ues repeatedly in the F42 high fructose corn syrup manufacturing process. This immobilized enzyme used in food processing make food free of enzyme after production, so there is no need to adopt the way of heat treatment to make enzyme inactivated, which can help improving the quality of food as well as economic benefits.

Isomerism process technical parameters:

For another, if you want to get the F55 or F90 high fructose corn syrup, use the F42 as basic material to manufacturing is high efficiency and convenience. After F42 high fructose corn syrup manufacturing process, just add the crystallization system and refining system can manufacturer F90 high fructose corn syrup. And to get F55, just mixed F90 with F42 with a suitable proportion.

For another, if you want to get the F55 or F90 high fructose corn syrup, use the F42 as basic material to manufacturing is high efficiency and convenience. After F42 high fructose corn syrup manufacturing process, just add the crystallization system and refining system can manufacturer F90 high fructose corn syrup. And to get F55, just mixed F90 with F42 with a suitable proportion.

To sum up, among is the introduction of Doing Company F42 high fructose corn syrup manufacturing process, technology and equipments. We can give you complete high fructose corn syrup manufacturing process equipments, F42, F55, F90 all is suitable. Before one of our client bought a set of F42 high fructose corn syrup manufacturing process equipment with annual capacity 10 million tons cost about $15,200,000, you can as a reference. But it's mention to tell you that different requests with different technology design, so the price also different, to get accurate price of our equipments, you need discuss with our engineer.

On the following use the starch for example to introduce the F42 high fructose corn syrup manufacturing process. High fructose corn syrup manufacturing process include starch liquefaction, saccharification and isomerism process. The manufacturing process flowchart as below:

F42 high fructose corn syrup manufacturing process

Starch slurry mixed with 30-35% dry solids and adjust its PH value to 6.0-6.4. Before put into α-enzyme, first add calcium, because calcium ions can stabilize the enzyme. Then mixed heat-stable α-enzyme (Novo’s Termamyl 120L) into the starch slurry, the slurry is instantaneously heated to 100 ℃ and held at this temperature for 10 min before it is cooled to 90 ℃. This temperature is maintained for 1-3h service for further hydrolyze the starch. Among this, it is the liquefaction process introduction in the F42 high fructose corn syrup manufacturing process.

Liquefaction process technical parameters:

| Starch slurry concentration | α-enzyme | PH value | Temperature | DE value |

| 32%-36% | 8-10g per ton dry starch |

before:6.0-6.4 after: 4.2-4.5 |

different value in different section | 15%-20% |

After this liquefying process complete in the F42 high fructose corn syrup manufacturing process, the starch has been transfered into dextrins with a dextrose equivalent (DE) between 15 and 20. (The physical properties of the syrup changed with the DE and the method of manufacture difference.) DE is the total reducing sugar in the syrup expressed as dextrose on a dry weight basis.

Doing Company high fructose corn syrup manufacturing process main equipments

Saccharification:

After liquefaction, the pH is reduced to between 4.2 and 4.5 and after the solution is cooled to 60 ℃. A glucomylase (Novo’s AMG 300L) is added immediately. The reaction time for saccharification is usually between 24-48 hour depending on enzyme reaction. Glucoamylase releases single glucose units from the ends of dextrin molecule. Syrups of 95% glucose or higher are manufactured. This is the saccharification process for the F42 high fructose corn syrup manufacturing process.

Saccharification process technical paramters:

| Glucomylase | PH value | DE value | Time cost |

| 0.45-0.58L per ton dry starch | 5.5 | 95%-98% | 50h per tank |

It's worth to tell you the liquefaction and saccharification step is the most important two parts of the F42 high fructose corn syrup manufacturing process from glucose. These steps performance influenced the glucose products quality directly. So the advanced technology and equipments select for the F42 high fructose corn syrup manufacturing process is very important.

Doing Company syrup equipments plant

Isomerism:

The purified glucose solution is isomerized by a reactor containing immobilized isomerase to obtain fructose syrup with 42% fructose content. It's honor to tell you that the isomerase we are using is a kind of immobilized enzyme. Converted from soluble state into immobilized state, the stability of isomerism will be increased significantly and it can be ues repeatedly in the F42 high fructose corn syrup manufacturing process. This immobilized enzyme used in food processing make food free of enzyme after production, so there is no need to adopt the way of heat treatment to make enzyme inactivated, which can help improving the quality of food as well as economic benefits.

Isomerism process technical parameters:

| Glucose concentration | PH value | Temperature | Conversion rate |

| 42% | 7.0-7.5 | 60-63℃ | 42% |

To sum up, among is the introduction of Doing Company F42 high fructose corn syrup manufacturing process, technology and equipments. We can give you complete high fructose corn syrup manufacturing process equipments, F42, F55, F90 all is suitable. Before one of our client bought a set of F42 high fructose corn syrup manufacturing process equipment with annual capacity 10 million tons cost about $15,200,000, you can as a reference. But it's mention to tell you that different requests with different technology design, so the price also different, to get accurate price of our equipments, you need discuss with our engineer.

Leave A Message About F42 high fructose corn syrup manufacturing process

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- In the high fructose corn syrup factory, to produce fructose, firstly ...

- Fructose syrup preparation machine used for fructose syrup productioni...

- The introduction of the fructose syrup production machineand its funct...

- The glucose fructose syrup production machine actually consists of the...

- Use the starch for example to introduce the F42 high fructose corn syr...

- High fructose syrup production is according to the starch processed by...

- High fructose syrup production process contain: mixing and liquidatio...

- we can provide you the different capacity corn syrup production proces...

- Above all is the description for high fructose corn syrup manufacturin...

- My company is very professional in manufacturing the complete high fru...