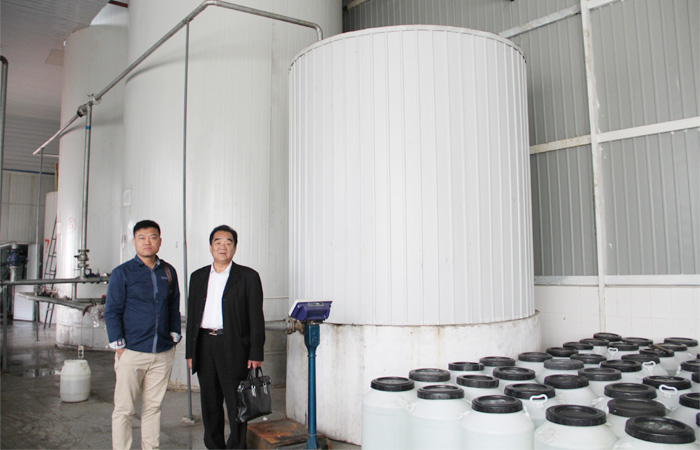

High fructose corn syrup factory

In the high fructose corn syrup factory, to produce fructose, firstly we need to get the glucose, use the enzyme method for starch hydrolysis.Doing Company can offer the tachnology data and equipments for your high fructise cirn syrup factory.

- Ms Elina Wu

- Phone:0086 135 2661 5783

- Email:sales@syrupmachine.com

In the high fructose corn syrup factory, to produce fructose, firstly we need to get the glucose, use the enzyme method for starch hydrolysis. During process for making fructose syrup, the first enzyme added is alpha-amylase which breaks the long chains down into shorter sugar chains – oligosaccharides. Glucoamylase is mixed in and converts them to glucose; the resulting solution is filtered to remove protein, then using activated carbon, and then demineralized using ion-exchange resins. The purified solution is then run over immobilized xylose isomerase, which turns the liquid to 50–52% glucose with some unconverted oligosaccharides, and 42% fructose (HFCS 42), and again demineralized and again purified using activated carbon. Some is processed into HFCS 90 by liquid chromatography, then mixed with HFCS 42 to form HFCS 55. So in the high fructose corn syrup factory, you can produce F55, F42 and F90 fructose. We will offer the technology data and the equipmets used in your high fructose corn syrup factory.

high fructose corn syrup factory overview

Then below is the main equipments and there function in high fructose corn syrup factory:

1.Mixing tank:

Mixing the starch and water to get the right density slurry, add certain enzyme, adjust the PH value and temperature to get the starch milk, in this condition, the starch will not be precipitated, the material used in high fructose corn syrup factory has been prepared for glucose produce.

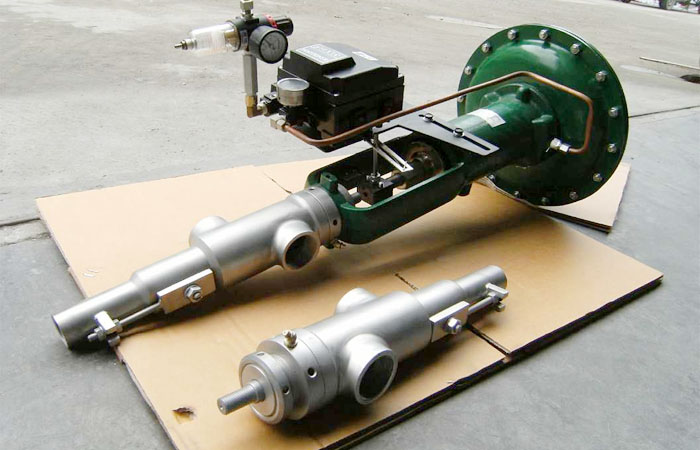

2. Liquefaction tank & ejector:

Used in the liquefaction process which can convert the starch milk into liquid dextrin, the liquefaction tank include the laminar tank, maintaining tank and neutralization tank in high fructose corn syrup factory. The liquid pumped by the ejector.

3. Plate frame filter press machine:

Actually in the high fructose corn syrup factory, this filter machine will be used in two sections, not only the deproteinization process, but also the decolorization. It's an important machine for the syrup purify. The deproteinization process function is used to separate the protein and other solid impurity from liquid dextrin, with automatic mechanical extrusion method.

And the decolorization process adopt the activated carbon adsorption principle to remove color from the liquid. The decolorization & decarbaurization normal sequence is the first decolorization-the first decarburization-The second decolorization-the second decarburization.

Plate frame filter press machine

4. Saccharification tank:

After liquefaction, the pH value is reduced to 4.2-4.5, when the solution temperature is cooled to 60 ℃, add the glucomylase (Novo’s AMG 300L) immediately. The reaction time for saccharification is usually between 24-48 hour depending on enzyme reaction speed. Glucoamylase releases single glucose units from the ends of dextrin molecule, syrups of 95% glucose or higher are manufactured by the saccharification tank, important for the fructose syrup production in high fructose corn syrup factory.

5. Ion exchange column:

Ion exchange can remove the Ca2+ and Mg2+ etc, and the negative ions, pure the syrup, the resin need regeneration by acid and alkali washing after working for some days. After the syrup liquid processed by ion exchange column, we can get the product can be eaten by people.

ion exchange column

6. Isomerism system:

This process used to converting glucose into fructose, the isomerism system can make the purified glucose solution isomerized by a reactor containing immobilized isomerase to obtain fructose syrup with 42% fructose content. It's honor to tell you that the isomerase we are using is a kind of immobilized enzyme. Converted from soluble state into immobilized state, the stability of isomerism will be increased significantly and it can be uses repeatedly in the high fructose corn syrup factory. This immobilized enzyme used in food processing make food free of enzyme after production, so there is no need to adopt the way of heat treatment to make enzyme inactivated, which can help improving the quality of food as well as economic benefits.

7. Syrup evaporator:

Evaporation process for fructose syrup production is aimed to remove the excess moisture from the syrup liquid. We will suggest you the most suitable type syrup evaporator as your production requests.

syrup evaporation

About high fructose corn syrup factory, there are some production solution and technical standard, use the annual capacity 5 million tons syrup as example:

1. Production method: double enzyme method for starch hydrolysis

2. Production schedule: 300 working days each year, 166.66ton corn syrup each day. The workers shift 8 hours a day, three shifts a day, each group production capacity 55.56t

3. Raw material: corn starch-starch content 85.4%, moisture 14%, fat(dry material) 0.1%, protein (dry material) 0.4%, gravity 0.1%

4. Product specifications: use corn starch or other type starch can make glucose, fructose and maltose as your select, Doing Company one set syrup equipments in high fructose corn syrup factory can produce this three type corn starch syrup.

5. Enzyme standard: high temperature resistance α-enzyme, activity 20000u/g, cost 8u/g. Saccharification enzyme activity 50000u/g, cost 200u/g. Isomerusm enzyme activity>360u/g.\

Note: among data just for reference, different area has different condition.

high fructose corn syrup factory overview

1.Mixing tank:

Mixing the starch and water to get the right density slurry, add certain enzyme, adjust the PH value and temperature to get the starch milk, in this condition, the starch will not be precipitated, the material used in high fructose corn syrup factory has been prepared for glucose produce.

2. Liquefaction tank & ejector:

Used in the liquefaction process which can convert the starch milk into liquid dextrin, the liquefaction tank include the laminar tank, maintaining tank and neutralization tank in high fructose corn syrup factory. The liquid pumped by the ejector.

3. Plate frame filter press machine:

Actually in the high fructose corn syrup factory, this filter machine will be used in two sections, not only the deproteinization process, but also the decolorization. It's an important machine for the syrup purify. The deproteinization process function is used to separate the protein and other solid impurity from liquid dextrin, with automatic mechanical extrusion method.

And the decolorization process adopt the activated carbon adsorption principle to remove color from the liquid. The decolorization & decarbaurization normal sequence is the first decolorization-the first decarburization-The second decolorization-the second decarburization.

Plate frame filter press machine

4. Saccharification tank:

After liquefaction, the pH value is reduced to 4.2-4.5, when the solution temperature is cooled to 60 ℃, add the glucomylase (Novo’s AMG 300L) immediately. The reaction time for saccharification is usually between 24-48 hour depending on enzyme reaction speed. Glucoamylase releases single glucose units from the ends of dextrin molecule, syrups of 95% glucose or higher are manufactured by the saccharification tank, important for the fructose syrup production in high fructose corn syrup factory.

5. Ion exchange column:

Ion exchange can remove the Ca2+ and Mg2+ etc, and the negative ions, pure the syrup, the resin need regeneration by acid and alkali washing after working for some days. After the syrup liquid processed by ion exchange column, we can get the product can be eaten by people.

ion exchange column

6. Isomerism system:

This process used to converting glucose into fructose, the isomerism system can make the purified glucose solution isomerized by a reactor containing immobilized isomerase to obtain fructose syrup with 42% fructose content. It's honor to tell you that the isomerase we are using is a kind of immobilized enzyme. Converted from soluble state into immobilized state, the stability of isomerism will be increased significantly and it can be uses repeatedly in the high fructose corn syrup factory. This immobilized enzyme used in food processing make food free of enzyme after production, so there is no need to adopt the way of heat treatment to make enzyme inactivated, which can help improving the quality of food as well as economic benefits.

7. Syrup evaporator:

Evaporation process for fructose syrup production is aimed to remove the excess moisture from the syrup liquid. We will suggest you the most suitable type syrup evaporator as your production requests.

syrup evaporation

About high fructose corn syrup factory, there are some production solution and technical standard, use the annual capacity 5 million tons syrup as example:

1. Production method: double enzyme method for starch hydrolysis

2. Production schedule: 300 working days each year, 166.66ton corn syrup each day. The workers shift 8 hours a day, three shifts a day, each group production capacity 55.56t

3. Raw material: corn starch-starch content 85.4%, moisture 14%, fat(dry material) 0.1%, protein (dry material) 0.4%, gravity 0.1%

4. Product specifications: use corn starch or other type starch can make glucose, fructose and maltose as your select, Doing Company one set syrup equipments in high fructose corn syrup factory can produce this three type corn starch syrup.

5. Enzyme standard: high temperature resistance α-enzyme, activity 20000u/g, cost 8u/g. Saccharification enzyme activity 50000u/g, cost 200u/g. Isomerusm enzyme activity>360u/g.\

Note: among data just for reference, different area has different condition.

- Prev:Nothing

- Next:Fructose syrup preparation machine

Leave A Message About High fructose corn syrup factory

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- In the high fructose corn syrup factory, to produce fructose, firstly ...

- Fructose syrup preparation machine used for fructose syrup productioni...

- The introduction of the fructose syrup production machineand its funct...

- The glucose fructose syrup production machine actually consists of the...

- Use the starch for example to introduce the F42 high fructose corn syr...

- High fructose syrup production is according to the starch processed by...

- High fructose syrup production process contain: mixing and liquidatio...

- we can provide you the different capacity corn syrup production proces...

- Above all is the description for high fructose corn syrup manufacturin...

- My company is very professional in manufacturing the complete high fru...