In the contemporary process, corn is milled for making fructose syrup by the professional fructose syrup making machine, to produce corn starch the "acid-enzyme" process is used in which the corn starch solution is acidified to begin breaking up the existing carbohydrates, and then enzymes are added to further metabolize the starch and convert glucose to fructose. Making fructose syrup requests three type enzyme: α-enzyme, saccharification enzyme and isomerusm enzyme. Adopt enzyme mehtod for making fructose syrup is the most advanced technology all over the world.

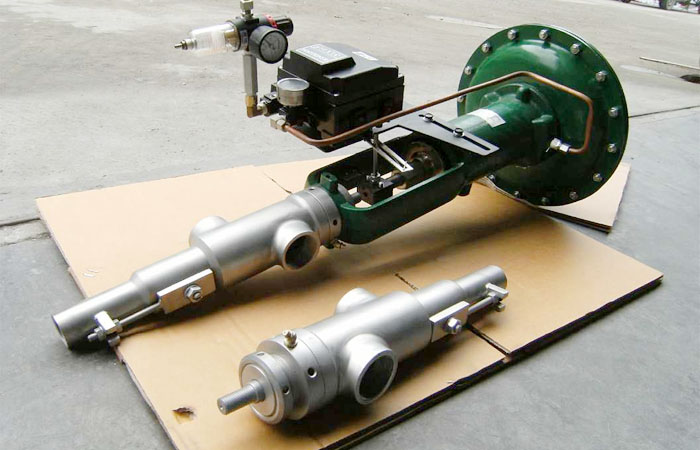

Machine for making fructose syrup

| Machine | Model/ Volume | Quantity |

| Mixing tank | volume 100L | 2 |

| Liquefaction tank | 24 m3 | 1 |

| Saccharification tank | 200 m3 | 3 |

| Ejector | power 504 kw | 2 |

| Motor | power 840 kw | 1 |

| Isomerism column | volumn 50L | 1 |

| Ion exchange column | 14 | |

| Filter press | 5000L/H | 4 |

| Vacuum cooler | volumn 12 m3 | 1 |

| Liquid-vapor seperator | volumn 12 m3 | 1 |

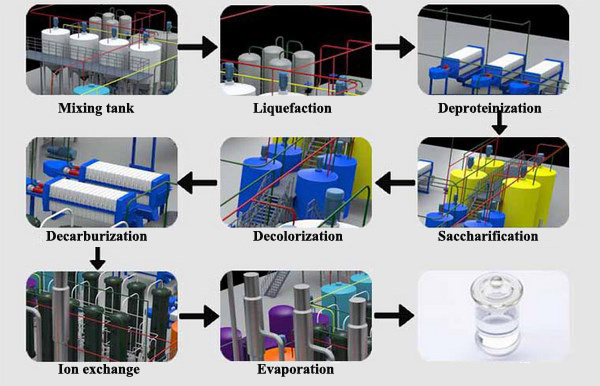

Below is Doing Company production process for making fructose syrup:

1. Corn starch mixing process:

Mixing the starch and water to get the right density slurry. Then add the α-enzyme and keep the temperature for particular time to make corn powder absorbing enough water for starch dextrinization. Requests the mixing tank in this process for making fructose syrup

2. Liquefaction process:

This liquefaction process is used to convert the starch into liquid dextrin. The starch slurry will be sprayed at high temperature by jet cooker. With the add of amylase and steam, the starch will be converted into liquid dextrin fastly.

Glucose syrup production process

3. Deproteinization for making fructose syrup:

The deproteinization process function is separate the starch protein and other solid impurity from liquid dextrin by filter press, usually the plate frame filter press machine, then the liquid dextrin will be pumped to next process, the corn protein can be left for sale, it's a good product for animal feeding.

4. Saccharification:

Saccharification process can convert the liquid dextrin into required DE value in the saccharification tank. This process should be run under specific temperature for some hours. For making high DE glucose syrup, it will cost more time. The saccharification tank is requested in this process for making fructose syrup.

High fructose corn syrup making machine

5. Decolorization process:

The decolorization process is removing the color of the glucose syrup by activated carbon adsorption principle. The glucose syrup which reached required DE will be pumped from saccharification tank into the decolorization tank, mixed with activated carbon at proper temperature.

6. Decarburization process:

The decarburization process is used to separating the activated carbon from the glucose syrup by filter press to get clear glucose syrup. The glucose syrup will flow into the slot and delivery by transfer tank to next step for making fructose syrup, the waste activated carbon will be left.

Ion exchange working principle

7. Ion exchange process:

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure glucose syrup for making high purity glucose syrup. The resin need regeneration by acid and alkali washing after working for some days.

8. Evaporation process:

The evaporation process is aimed to evaporate the excedd water inside the glucose syrup to increase the DS of glucose syrup to the requirement (45%) before isomerisation. We will suggest you the most suitable syrup evaporator for you to making fructose syrup.

9. Isomerism process in fructose syrup production machine

The isomerism process can convert the glucose into fructose syrup with the used of isomerase. The glucose is converted into with 42% content of fructose syrup. This process and below process section is special for making fructose syrup, if you just want to get the glucose, then no need these section.

Syrup evaporator

10. Decolorization process- 11.Decarburization process- 12.Ion exchange process- 13.Evaporation process

After evaporation process, the DS of fructose syrup reach to the requirement (DS around 71%).

During process for making fructose syrup, the first enzyme added is alpha-amylase which breaks the long chains down into shorter sugar chains – oligosaccharides. Glucoamylase is mixed in and converts them to glucose; the resulting solution is filtered to remove protein, then using activated carbon, and then demineralized using ion-exchange resins. The purified solution is then run over immobilized xylose isomerase, which turns the liquid to 50–52% glucose with some unconverted oligosaccharides, and 42% fructose (HFCS 42), and again demineralized and again purified using activated carbon. Some is processed into HFCS 90 by liquid chromatography, then mixed with HFCS 42 to form HFCS 55. Among is the totally introduction of our method and machine for making fructose syrup.

- Prev:What's the technology for making glucose syrup from starch?

- Next:What's the production of glucose syrup using enzyme hydrolysis method

Leave A Message About What's the method for making fructose syrup ?

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...