For a completed corn starch maltose syrup production plant, it is finished by many different steps(mainly include 8 parts). Below is the description of production of maltose syrup from starch by Doing Company:

1.Corn starch mixing section

Corn starch is mixed with warm water. PH is adjusted 5.0-6.0, keep 30-40mints. ensure the enough mixting. It's worth to say, except corn starch, may other kinds of starch also can be used for maltose syrup production, like wheat starch, potato starch, cassava starch, etc, also rice powder.

2. Continuous spray liquefaction section for production of maltose syrup from starch:

Spray liquefaction: Heating all tanks by steam, then start liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity. Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect. Then send passed material to the second Liquid ejector, and keep temperature.

Maltose syrup production tanks

3.Filtration section for production of maltose syrup from starch:

Remove some corn gluten by filter press if there is.

4.Saccharification section

The liquefied liquid (solid content of 30% -35%) is pumped to the saccharification tank and cooled to 60°C in the process of production of maltose syrup from starch. Adding acid to adjust the pH to around 4.5. The brix is 31-32Bx; the adjusted concentration is 34.67% -35.6%; adding the saccharification enzyme is equivalent to 0.45-0.58L / ton dry starch. The liquefied liquid DE value is 28.85% -31.53%, the pumping time is 4-6 hours for one tank. Each tank of saccharification time is 50 hours. The DE value is about 95-97 when finished. The saccharification liquid is pumped into the pre-coated perlite drum filter to separate protein for production of maltose syrup from starch, and then entering the third time injectors for enzyme deactivation after saccharification. The third injection temperature is about 99℃; the injection pressure is 0.39Mpa; and the saccharification liquid yield is about 98% -105%.

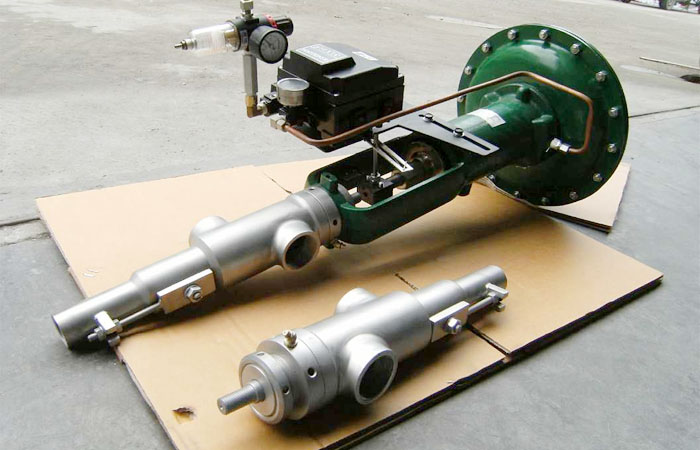

DOING syrup filter press

5.Decolorization section in production of maltose syrup from starch

Carry passed syrup into decolorization tanks (mixer and coil pipe are set in saccharification tank) by pump. Decolor by activated carbon

6.Filtration section in maltose syrup production plant production process:

(1) Filter protein and activated carbon for production of maltose syrup from starch by plate-and-frame filter press machine.

(2) Carry away protein by bottom slot for plate-and-frame filter press machine

(3) Unclean syrup is sent to big buffer tanks by pump.

(4) Carry clean syrup into buffer tanks.

Ion exchange column

7. Ion exchange section

(1) Carry syrup into Ion exchange columns in the process of production of maltose syrup from starch. Resin clean syrup in ion exchange columns. Then carry clean syrup into buffer tanks.

(2) When resin loses effect, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

(3) Recover resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till resin has function.

Syrup evaporation machine

8.Evaporation section and final maltose syrup

After ion exchange, the syrup will be pumped into the storage tank for production of maltose syrup from starch, after heating exchange and then enter into the evaporator. Evaporate syrup by Triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to final-product storage tanks by pumps. Evaporator commonly used multiple-effect evaporator for example three-effect etc. Pump the ion exchange liquid syrup into the three-effect evaporator for production of maltose syrup from starch. The first effect evaporator vacuum degree is 0.01-0.03Mpa, the temperature is about 105 ℃, the second-effect evaporator vacuum degree is 0.015-0.028Mpa, the temperature is 84 ℃ -90 ℃ , the third-effect evaporation vacuum degree is 0.04-0.05Mpa, the temperature is 55 ℃ -60 ℃ etc. After evaporation, it will be the high density liquid syrup according to the requirement.

1.Corn starch mixing section

Corn starch is mixed with warm water. PH is adjusted 5.0-6.0, keep 30-40mints. ensure the enough mixting. It's worth to say, except corn starch, may other kinds of starch also can be used for maltose syrup production, like wheat starch, potato starch, cassava starch, etc, also rice powder.

2. Continuous spray liquefaction section for production of maltose syrup from starch:

Spray liquefaction: Heating all tanks by steam, then start liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity. Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect. Then send passed material to the second Liquid ejector, and keep temperature.

Maltose syrup production tanks

Remove some corn gluten by filter press if there is.

4.Saccharification section

The liquefied liquid (solid content of 30% -35%) is pumped to the saccharification tank and cooled to 60°C in the process of production of maltose syrup from starch. Adding acid to adjust the pH to around 4.5. The brix is 31-32Bx; the adjusted concentration is 34.67% -35.6%; adding the saccharification enzyme is equivalent to 0.45-0.58L / ton dry starch. The liquefied liquid DE value is 28.85% -31.53%, the pumping time is 4-6 hours for one tank. Each tank of saccharification time is 50 hours. The DE value is about 95-97 when finished. The saccharification liquid is pumped into the pre-coated perlite drum filter to separate protein for production of maltose syrup from starch, and then entering the third time injectors for enzyme deactivation after saccharification. The third injection temperature is about 99℃; the injection pressure is 0.39Mpa; and the saccharification liquid yield is about 98% -105%.

DOING syrup filter press

Carry passed syrup into decolorization tanks (mixer and coil pipe are set in saccharification tank) by pump. Decolor by activated carbon

6.Filtration section in maltose syrup production plant production process:

(1) Filter protein and activated carbon for production of maltose syrup from starch by plate-and-frame filter press machine.

(2) Carry away protein by bottom slot for plate-and-frame filter press machine

(3) Unclean syrup is sent to big buffer tanks by pump.

(4) Carry clean syrup into buffer tanks.

Ion exchange column

(1) Carry syrup into Ion exchange columns in the process of production of maltose syrup from starch. Resin clean syrup in ion exchange columns. Then carry clean syrup into buffer tanks.

(2) When resin loses effect, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

(3) Recover resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till resin has function.

Syrup evaporation machine

After ion exchange, the syrup will be pumped into the storage tank for production of maltose syrup from starch, after heating exchange and then enter into the evaporator. Evaporate syrup by Triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to final-product storage tanks by pumps. Evaporator commonly used multiple-effect evaporator for example three-effect etc. Pump the ion exchange liquid syrup into the three-effect evaporator for production of maltose syrup from starch. The first effect evaporator vacuum degree is 0.01-0.03Mpa, the temperature is about 105 ℃, the second-effect evaporator vacuum degree is 0.015-0.028Mpa, the temperature is 84 ℃ -90 ℃ , the third-effect evaporation vacuum degree is 0.04-0.05Mpa, the temperature is 55 ℃ -60 ℃ etc. After evaporation, it will be the high density liquid syrup according to the requirement.

- Prev:How to make glucose syrup without cream of tartar ?

- Next:How is rice syrup made by industry production ?

Leave A Message About Technology method for production of maltose syrup from starch

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...