The process of making high fructose corn syrup method: enzymatic hydrolysis(α-amylase, glucoamylase, isomerase). It has high specificity, few by-products, high purity and light sugar color, which reduces the purification process and the amount of purifying agent. Compared with the acid method, it can convert higher concentration of solids, improve efficiency, reduce loss and reduce The cost, the obtained mother liquor can also be utilized, and it is carried out under normal temperature and pressure, and the equipment process is relatively simple.

DOINF high fructose corn syrup making machine

1. Brief technology process of making high fructose corn syrup

Starch milk → liquefaction → saccharification → decolorization & filtration → ion exchange → isomerization → decolorization filtration → ion exchange → concentration → 42% fructose syrup → adsorption separation → 90% pure fructose syrup

2. Process operation description:

(1) liquefaction: the concentration of 30% starch milk, adjust the pH value of 5.7.0, add α-amylase 5 ~ 10ml / g dry starch, temperature 85-90 ° C, for a certain period of time, until the iodine reaction is not obvious blue.

Liquefaction tank

(2) Saccharification: Adjust the pH value to 4.4.5, add glucoamylase, control the temperature at 60 ° C, stir the reaction for about 36 hours, make the DE value reach 93%-97%, decolorize and filter, ion exchange, vacuum concentration to the concentration 35%-45%.

(3) Isomerization: using immobilized isomerase (Sweetzyme T), which can catalyze the isomerization reaction between D-glucose and D-fructose, and add it to the sugar solution with a concentration of 35%-45%. Add 40-50mg / l of magnesium ions as a stabilizer, the pH of the column syrup is 7.7.8, the temperature is 55-60 ° C, and the pH of the isomerized sugar is 6.5-7.0.

(4) Concentration: After decolorization filtration, ion exchange, and vacuum concentration to 70%-75%, 42% fructose syrup is obtained.

If 42% of the fructose syrup is partially separated from the glucose, 55% fructose syrup is obtained, and 42% of the fructose syrup is adsorbed and separated to obtain 90% pure fructose syrup.

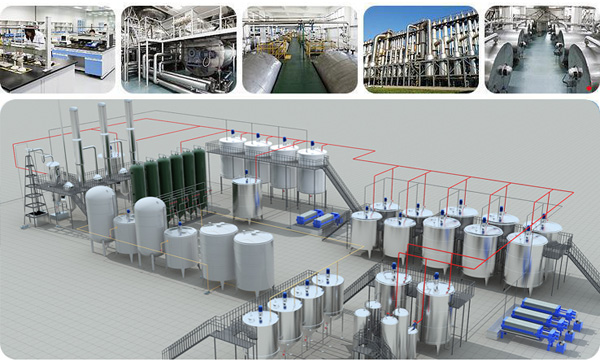

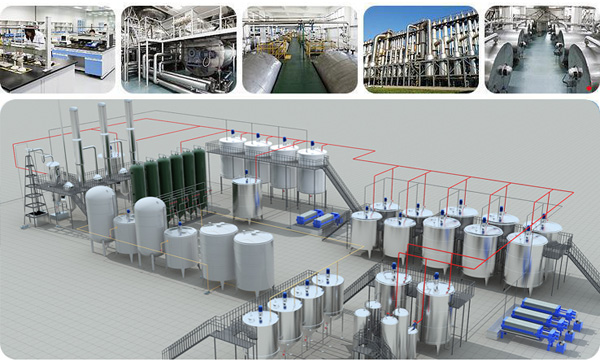

High fructose corn syrup production plant

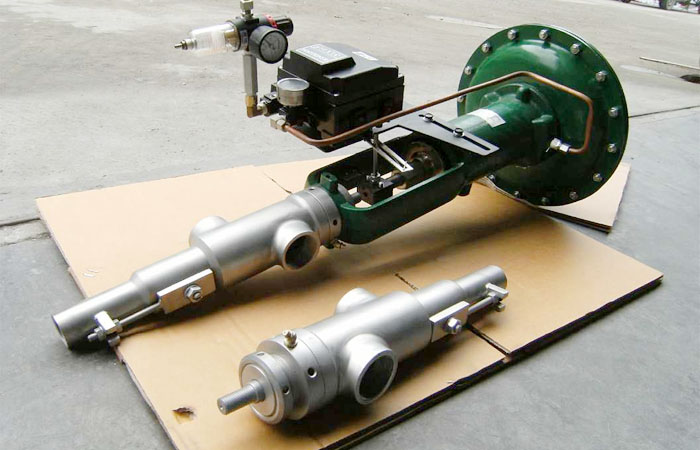

Main equipment: liquefaction tank, saccharification tank, filter, ion exchange column, syrup evaporator.

Product description: Glucose is produced by glucose isomerase to produce fructose. The syrup prepared is called fructose syrup. According to the content of fructose in syrup, the first generation fructose syrup with fructose content of 42% and fructose content is 55% of second-generation fructose syrup and 90% pure fructose syrup. Fructose syrup has high sweetness, high osmotic pressure than sucrose, is not easy to crystallize, and has good moisturizing properties. Therefore, it can be widely used in beverages, cakes production to instead of sucrose.

DOINF high fructose corn syrup making machine

Starch milk → liquefaction → saccharification → decolorization & filtration → ion exchange → isomerization → decolorization filtration → ion exchange → concentration → 42% fructose syrup → adsorption separation → 90% pure fructose syrup

2. Process operation description:

(1) liquefaction: the concentration of 30% starch milk, adjust the pH value of 5.7.0, add α-amylase 5 ~ 10ml / g dry starch, temperature 85-90 ° C, for a certain period of time, until the iodine reaction is not obvious blue.

Liquefaction tank

(3) Isomerization: using immobilized isomerase (Sweetzyme T), which can catalyze the isomerization reaction between D-glucose and D-fructose, and add it to the sugar solution with a concentration of 35%-45%. Add 40-50mg / l of magnesium ions as a stabilizer, the pH of the column syrup is 7.7.8, the temperature is 55-60 ° C, and the pH of the isomerized sugar is 6.5-7.0.

(4) Concentration: After decolorization filtration, ion exchange, and vacuum concentration to 70%-75%, 42% fructose syrup is obtained.

If 42% of the fructose syrup is partially separated from the glucose, 55% fructose syrup is obtained, and 42% of the fructose syrup is adsorbed and separated to obtain 90% pure fructose syrup.

High fructose corn syrup production plant

Leave A Message About What is the process of making high fructose corn syrup ?

- Director: Ms Elina Wu

- Phone: 0086 135 2661 5783

- WhatsApp: 0086 135 2661 5783

- Tel: 0086 371 5677 1822

- sales@syrupmachine.com

- Chat Online

- The step of corn syrup extracted from corn consists mainly of two part...

- About how is corn syrup processed,in there,Doing Company will give you...

- Answer for what is starch sugar,introduce the starch sugar types,appli...

- This is the starch and sugar conversion process introduction,overview ...

- amylase and saccharification enzyme are the main enzymes involved in s...

- This is the Doing Company answer for how is corn syrup made in factory...

- This is answer for how making glucose syrup,brief glucose syrup making...

- This is Doing Company answer for what is the process of making corn st...

- Cornstarch syrup recipe introduction from Doing Company,this is the co...

- Syrup production system introduction from Doing Company,the syrup prod...